DigivibeMX设备状态监测软件

DigivibeMX设备状态监测软件

DigivibeMX® Wireless Vibration Analyzer and Data Collector is replacing analyzers all over the world. Its’ easy connectivity and fast data collection times make it the most convenient solution for vibration analysis today.

DigivibeMX® products are the most fully functional vibration analyzers on the market. They integrate advanced functions for Vibration Analysis and Dynamic Balancing with new Triaxial Wireless technology, making them more portable and versatile.

HOJOLO TECHNOLOGIES

DigivibeMX® | Vibration Analyzer & Data Collector

DigivibeMX® Wireless Vibration Analyzer and Data Collector is replacing analyzers all over the world. Its’ easy connectivity and fast data collection times make it the most convenient solution for vibration analysis today.

DigivibeMX® products are the most fully functional vibration analyzers on the market. They integrate advanced functions for Vibration Analysis and Dynamic Balancing with new Triaxial Wireless technology, making them more portable and versatile. Furthermore, their compatibility with current mobile devices make them very easy to use and ultra-portable. Meet our improved functions for bearing and gearbox analysis and our new Machine Learning tool!

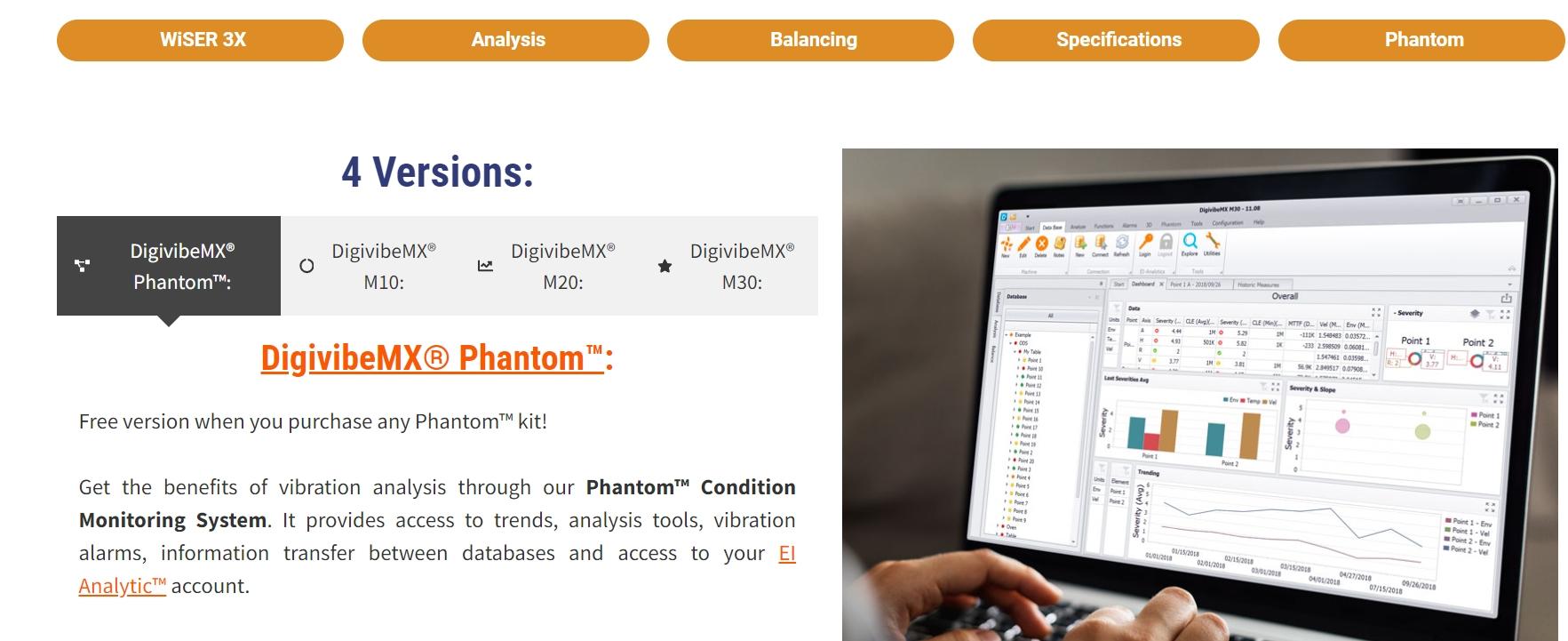

DigivibeMX® – Vibration collector and analyzer with Wireless Technology

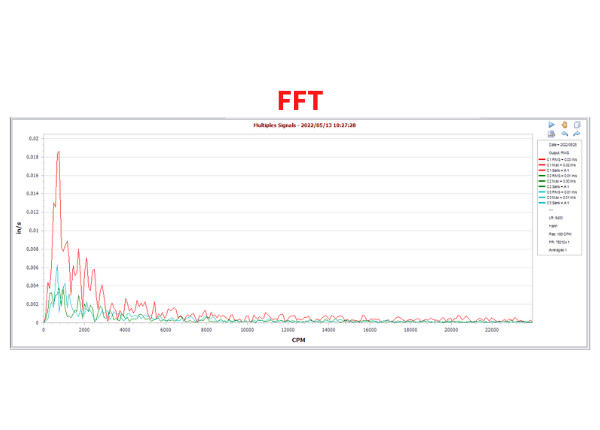

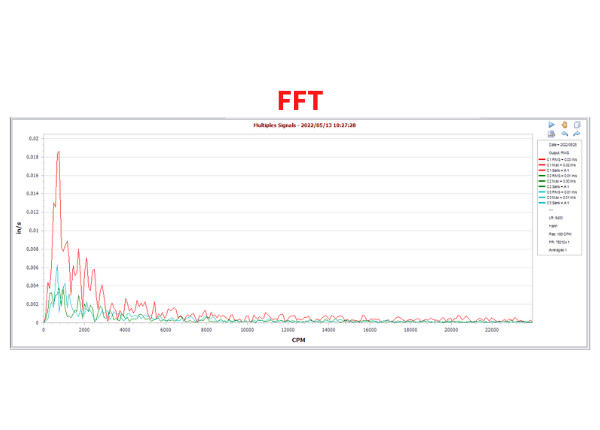

Vibration Analyzers have never been so portable. Our Triaxial Accelerometer communicates with mobile phones and computers in real time. So, DigivibeMX® is able to generate an FFT of more than 1 Million lines of resolution. Additionally, we created apps for iOS and Android that complement and communicate with each other, and the best thing is that they are all included in the package.

SQL database support

DigivibeMX® offers a range of database compatibility, including SQLce, MySQL, SQL Server, and SQL Azure. This means that the process of creating and visualizing your machine information becomes even simpler.

Our user-friendly interface simplifies the task of setting up your machine structure. You can effortlessly add your bearings and gearboxes, and further streamline the process by assigning alarm values for your machines. With the help of visual indicators, you’ll be equipped to swiftly identify significant vibration, acceleration, and acceleration envelope data, ensuring comprehensive monitoring and analysis of your equipment’s performance.

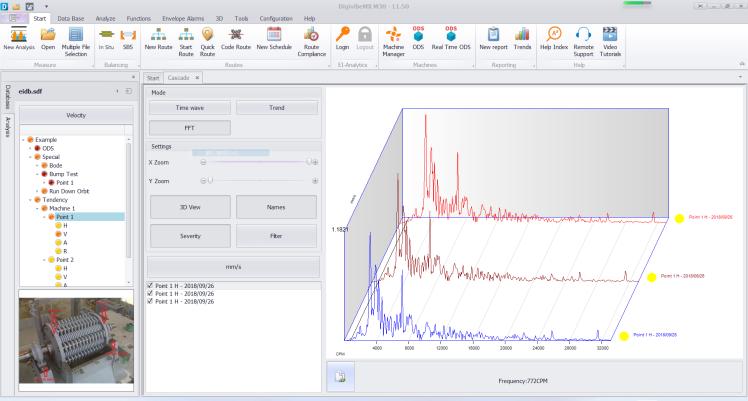

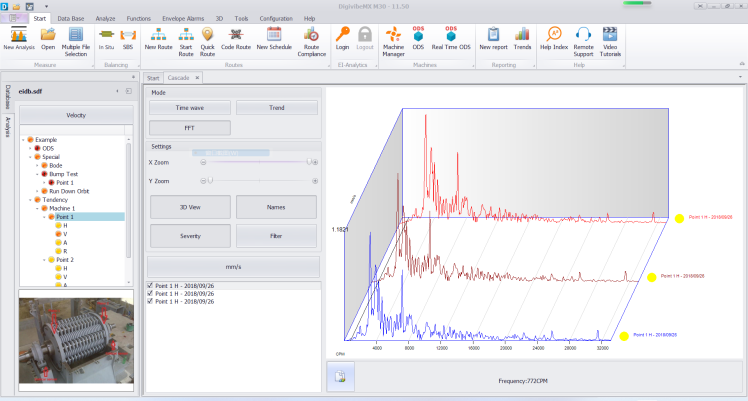

Get to know the 3D experience in our vibration analyzer DigivibeMX®

With DigivibeMX®, you can take your vibration analysis to the next level with the inclusion of ODS (3D movement and deformation simulations).

You have the option to use our extensive 3D library or seamlessly upload your own 3D model for performing Operational Deflection Shapes (ODS) simulations, which provide insight into 3D movement and deformation with vibration simulations.

The process of conducting 3D vibration simulations has been simplified to just one click, making it more accessible than ever. Even for users with limited experience, the interpretation of results is straightforward, allowing for in-depth analysis and enhanced insights into your machinery’s behavior.

Create routes and identify your machines with a code

The DigivibeMX® QR code generator for machines is a powerful tool for simplifying the identification and route data capture process.

By utilizing these QR codes, you can streamline the entire workflow. Simply scan the codes with our vibration analyzer to effortlessly capture measurements and gain immediate access to vital machine information. This user-friendly approach not only facilitates data collection but also enhances your machine management capabilities, ensuring you have rapid access to the insights required to maintain and optimize performance. It’s an invaluable feature that empowers efficient and effective maintenance practices.

Smart Vibration Analyzer – Machine Learning

If you’re unsure about the appropriate values for your machinery, DigivibeMX® has a solution for you!

Our vibration analyzer is equipped with a Machine Learning feature that allows your equipment to teach itself. You can specify a learning period for Velocity and Acceleration Envelope, enabling the system to adapt to your machine’s unique behavior. This means you can create custom Severity Alarms that align with your equipment’s specific characteristics.

Additionally, we’re working on implementing a feature that will soon allow you to receive email notifications for these alarms. This comprehensive approach ensures that your maintenance and monitoring processes are not only personalized but also proactive, enhancing the efficiency and reliability of your operations.

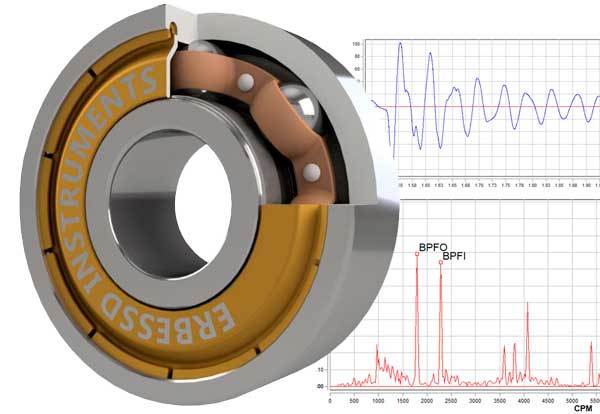

Analyze your Bearings with DigivibeMX®

Incorporating a wealth of resources, our vibration analyzer boasts a comprehensive bearing database featuring over 25,000 items. This invaluable resource not only provides essential dimensions but also includes data on failure frequencies, making the diagnosis of your bearings both straightforward and precise.

Particularly noteworthy are the specific frequencies linked directly to the geometry of the rolling elements within your bearings. These frequencies are continuously monitored by our software, serving as an early warning system for potential premature failures. This proactive approach allows you to preventt unscheduled downtime, ensuring the uninterrupted performance of your machinery and the longevity of your operations.

Collect data on your smartphone. Vibration Analyzer in the palm of your hand.

Record routes on your phone or tablet with the same quality, at no cost. Your data will be uploaded automatically to the cloud or via QR connect directly to your DigivibeMX® local software…and you can analyze it on your mobile, computer or directly from your browser.

Share your cloud data with your customers

Create your free EI Analytic™ account, collect data and analyze it anywhere from your mobile devices.

With the cloud platform you can share your information with anyone, it’s free. Your customers will be able to check the status of their machines whenever they want. Even view spectra online.

Experience the cloud-based Vibration Analyzer: EIAnalytic™.

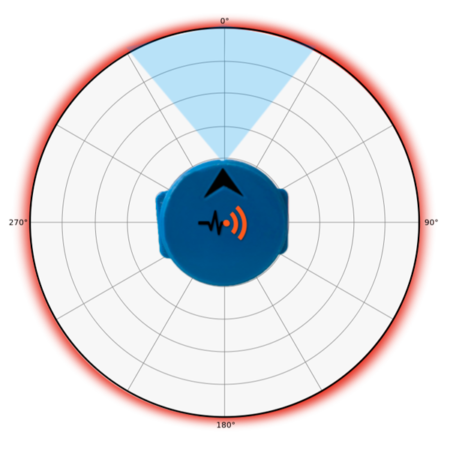

Bluetooth angle meter

We offer a unique wireless angle meter on the market. Place it on your shaft and our vibration analyzer will automatically calculate the position of the counterweight by just rotating the rotor.

Our angle sensor connects via Bluetooth to DigivibeMX® to make it easy to position the correct weight at the right angle. Place it in front of the shaft and align it with the mark on the RPM sensor.

The rest is up to us.

4 Channels analysis with DigivibeMX®

Do you want to record 4 channels simultaneously?

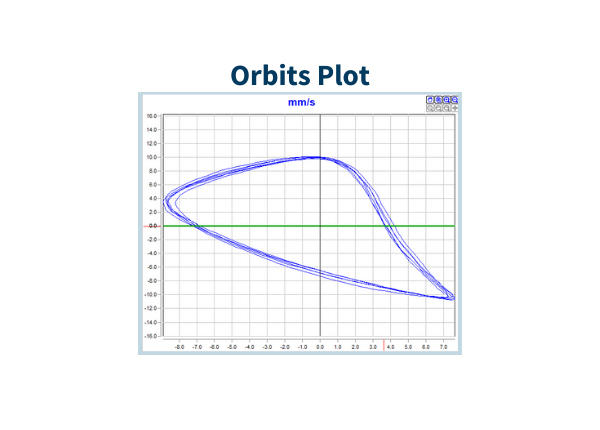

Our wired interface and wireless accelerometers are capable of simultaneous 4 channels recording. Hence, you can use it to measure phase between all of them, or simply to make routes faster.

Examine the data collected in DigivibeMX® and analyze your data with our tools.

Change your without loosing data

Is your tablet damaged? Do you want to update your PC?

Just change it, the license is already yours and the software can be installed on any computer at no additional cost. Our system makes your replacement cost as low as simply buying a new commercial computer.

We know that computer equipment does not last forever. Therefore, our system does not require a unique “Brain”. Additionally, the software can be installed in 2 additional desktop computers to make the analysis job easier.

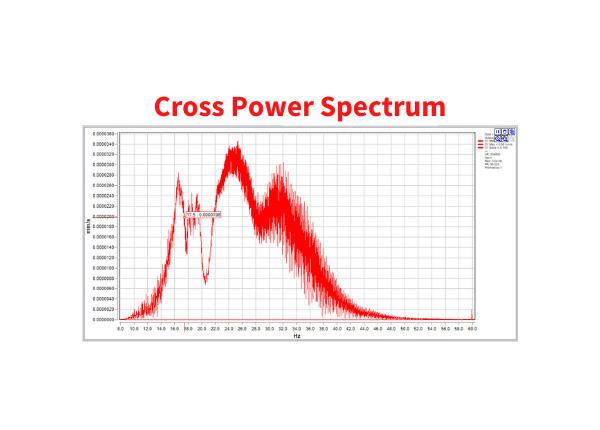

Vibration analyzer with advanced functions

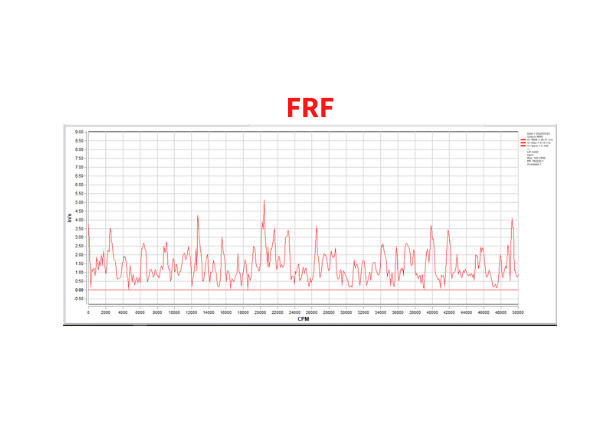

Our vibration analyzers also have advanced functions such as:

Bode diagram

Nyquist diagram

Circular Time Wave Form

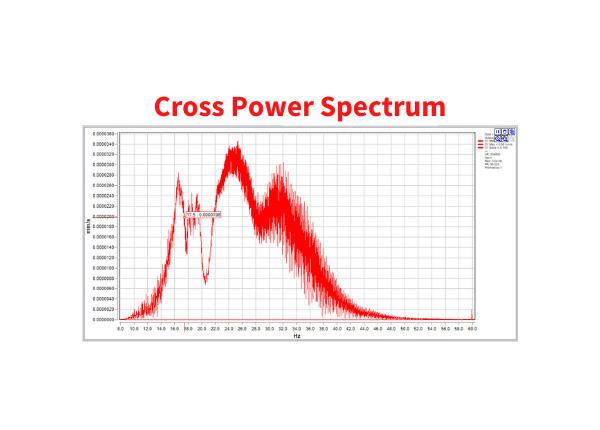

Cross Power Spectrum

Frequency Response Function

Multichannel phase analysis

Analysis of very low speed bearings

Condition monitoring, colector and analyzer

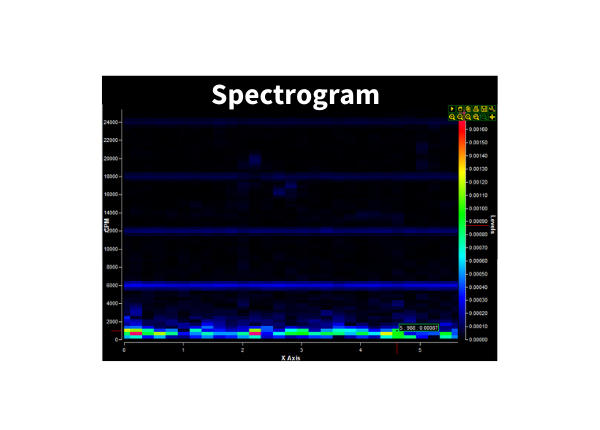

Need to identify changes in the behavior of your machines?

Our Phantom™ Condition Monitoring System will allow you to have better control of your machine information. Set up email or smartphone notifications, create trends and measure parameters such as current, RPM, temperature and more.

Compatible with local databases, our EIAnalytics™ cloud and Modbus TCP/IP.