电动汽车传动系统新型多功能断开离合器技术

文章摘要

随着电动汽车市场的快速增长,电动汽车传动系统正在经历重新定义,创造下一代推进系统。这些系统需要在功能、效率、续航里程和成本方面进一步优化。Amsted Automotive(梅恩斯工业)开发了一种可控断开离合器和执行技术,具有完全断开和锁定功能,以及可控双向单向离合器操作的附加功能。

这项技术为电动汽车传动系统提供了新颖和灵活的系统解决方案,特别是在电动全轮驱动(eAWD)和主驱动力单元(EDU)应用中。此外,该技术还可以与多速换挡功能、上坡辅助和停车锁止特性相结合,为下一代电动汽车传动系统创造新颖的多功能离合器解决方案。预计这些技术将减少质量、提高传动效率,并降低与电动汽车推进控制策略相关的成本和复杂性。

正文

John Jennings, Dustin Finn, Tim Hunter

约翰·詹宁斯,达斯汀·芬恩,蒂姆·亨特

Amsted Automotive (Means Industries)

安斯特汽车(梅恩斯工业)

1 Abstract

摘要

Electric Vehicles (EV) drivetrain systems are being redefined – creating nextgeneration propulsion systems as the EV market grows rapidly. This next generation of EV propulsion systems will need to be further optimized for function, efficiency, range and cost as the EV market scales up. This includes the need for new solutions to facilitate seamless eAWD disconnect with the ability to quickly and reliably shift between forward propulsion, coast (disconnect), regeneration, and reverse modes. Design flexibility is also required for adaptability at multiple locations between the eMachine and wheels.

电动汽车(EV)传动系统正在被重新定义——随着电动汽车市场的快速增长,创造下一代推进系统。随着电动汽车市场扩大规模,这一代电动汽车推进系统需要进一步优化功能、效率、续航里程和成本。这包括需要新的解决方案来促进无缝eAWD断开连接,并能够快速可靠地在前进推进、滑行(断开)、再生和倒车模式之间切换。还需要设计灵活性,以便在电动机和车轮之间的多个位置进行适应。

In addition to disconnects, next generation EV drivetrains will also require more sophisticated solutions for electronic park lock, hillhold and multispeed shifting, combining the functions of historical ICE transmissions and drivelines. These tech nologies can be applied to EV passenger cars, light truck and commercial vehicles.

除了断开连接外,下一代电动汽车传动系统还需要更复杂的电子驻车锁、上坡辅助和多速换挡解决方案,结合了历史内燃机变速箱和驱动系统的功能。这些技术可以应用于电动汽车乘用车、轻型卡车和商用车。

Amsted Automotive (Means Industries) has developed a controllable disconnect clutch and actuation technology with full disconnect and locking functions, with the additional functionality for controlled bidirectional onewayclutch operation. This technology, when applied to EV drivetrains, can provide novel and flexible system solutions for EV disconnects for both eAWD and primary drive EDU applications. The control and flexibility of this technology can also enable the same disconnect function and advantages for the primary drive axle EDU.

阿姆斯特汽车(梅恩斯工业)已开发出一种可控的断开离合器和执行技术,具有完全断开和锁定功能,并具备可控的双向单向离合器操作附加功能。当应用于电动汽车传动系统时,这项技术可以为电动全轮驱动(eAWD)和主驱动力单元(EDU)应用提供新颖且灵活的系统解决方案。这种技术的控制和灵活性还可以为前驱动力轴EDU实现相同的断开功能和优势。

Additional capability can also be combined with multispeed shift functions, hillhold and parklock features to create novel multifunctional clutch solutions for the next generation of EV drivetrains.

附加功能还可以与多速换挡功能、上坡辅助和停车锁止特性相结合,为下一代电动汽车传动系统创造新颖的多功能离合器解决方案。

The first baseline disconnect for EV application was launched into production in 2021. The next generation of Disconnect Clutch Systems include overrunning functionality to achieve a controlled bidirectional onewayclutch function. This is cur rently being developed for applications on a production path. These technologies are expected to reduce mass, improve drivetrain efficiencies, and reduce the cost and complexity associated with EV propulsion controls strategies.

EV应用的第一个基线断开器已于2021年投入生产。下一代断开离合系统包括过载功能,以实现可控的双向单向离合器功能。目前正在为生产路径上的应用开发这些技术。预计这些技术将减少质量、提高传动效率,并降低与电动汽车推进控制策略相关的成本和复杂性。

Keywords: Disconnect, eAxle, eDrive, EV Shifting, MultiSpeed EV Gear Box

关键词:断开连接、e轴、电驱动、电动汽车换挡、多速电动汽车变速箱

First Producton Dynamic Diconect Clutch for Electric Vehicle

第一代电动汽车用动态断开离合器

2 Introduction: Emerging Dynamics in EV Drivetrains

The EV & Electrified Vehicle market is growing at a fast pace, and this has created new and unique challenges for our industry: OEMs and Tier 1 Automotive Suppliers – both established and new – need to develop new approaches for electri fication. Simply put, traditional internal combustion engine (ICE) drivetrains and electric drivetrains are not the same. Without this ability to adapt to the unique requirements of EV powertrain systems, there may be missed opportunities for new success within the transportation sector.

2 引言:电动汽车驱动系统的动态变化

电动汽车和电动化汽车市场正在快速增长,这为我们行业带来了新的独特挑战:原始设备制造商(OEM)和一级汽车供应商——无论是老牌还是新晋企业——都需要为电气化开发新的方法。简单来说,传统的内燃机(ICE)驱动系统和电动驱动系统并不相同。如果没有适应电动汽车动力系统独特要求的能力,可能会错失交通领域内新的成功机会。

As emerging products for EV propulsion systems continue to be redefined and reinvented, Amsted Automotive has focused on optimizing products for function, efficiency, package, and cost, in order to help its customers meet emissions standards and other electrification targets. Means Industries, an Amsted Automotive company, has developed a novel multifunctional clutch technology that offers its customers efficient and intelligent Torque Management Solutions: Dynamic Controllable Clutch (DCC) and ElectroMechanical Eaxle Disconnect Solutions.

随着电动汽车推进系统的新产品不断被重新定义和革新,Amsted Automotive专注于优化产品的功能、效率、包装和成本,以帮助其客户满足排放标准和其他电气化目标。作为Amsted Automotive公司之一的Means Industries,已经开发出一种新颖的多功能离合器技术,为客户提供高效智能的扭矩管理解决方案:动态可控离合器(DCC)和电机械轴分离解决方案。

Modern Electric Vehicle Platform

现代电动汽车平台

3 Traditional ICE AWD Architecture

3 传统内燃机全轮驱动架构

As an example, the illustration below shows a typical frontwheelwheel (FWD) based ondemand allwheeldrive (AWD) architecture. This includes a transversely mounted internal combustion engine (ICE), transmission (transaxle), powertake off unit (PTU), and a reardriveunit (RDU) containing a frictionbased AWD coupler.

作为一个例子,下面的插图展示了一个典型的前轮驱动(FWD)基于需求的四轮驱动(AWD)架构。这包括一个横向安装的内燃机(ICE)、变速箱(变速器)、动力取出口单元(PTU)和一个包含摩擦式AWD耦合器的后驱动单元(RDU)。

Allwheeldrive (AWD) is achieved by splitting the powerflow from the ICE and transmission at the PTU. Torque and power to the rear wheels is transferred through the PTU to the propshaft, RDU and rear halfshafts. Torque and power to the front wheels is transferred directly from the output of the transmission to the front halfshaft and front wheels. The percentage of driveline torque and power transferred to the rear wheels is controlled and modulated by the RDU coupler.

全轮驱动(AWD)是通过在PTU处从内燃机和变速箱中分割动力流来实现的。后轮的扭矩和功率通过PTU传递到传动轴、RDU和后半轴。前轮的扭矩和功率直接从变速箱的输出端传递到前半轴和前轮。通过RDU耦合器控制和调节传输至后轮的传动系扭矩和功率的比例。

The purpose of the AWD disconnect is to stop the AWD function in order to improve vehicle efficiency and fuel economy when AWD is not required. The system has a disconnect devices in both the PTU and RDU that stops the rotation of the PTU, RDU and propshaft. Typically, a dog clutch or sliding sleeve is used to disconnect the PTU, and the RDU coupler is used as a system synchronizer and disconnect for the RDU. During disconnect mode parasitic drag losses are reduced or eliminated. This includes the hypoid gear meshes in the PTU and RDU, bearing drag, seal drag, fluid churning losses and spin losses from the propshaft and propshaft joints.

AWD断开装置的目的在于停止四轮驱动功能,以提高车辆效率和燃油经济性,在不需要四轮驱动时。该系统在PTU(前传动单元)和RDU(后传动单元)中都有断开装置,可以停止PTU、RDU和传动轴的旋转。通常,使用齿形离合器或滑套来断开PTU,而RDU耦合器用作系统的同步器和RDU的断开装置。在断开模式下,寄生拖拽损失会减少或消除。这包括PTU和RDU中的锥齿轮啮合、轴承拖拽、密封件拖拽、流体搅动损失以及传动轴和传动轴关节的旋转损失。

During the disconnect and reconnect functions, there can be no compromise in AWD function. Seamless disconnect and reconnect of the rear driveline is required while the vehicle is in motion and while the ICE powertrain continues to apply torque to the front axle. The most critical challenge is synchronization during AWD reconnect. This can be inhibited by block shifts and shift interruptions with the dog clutch, matching rear wheel speed with the ICE/transmission output, high inertial torque of the rear driveline system, cold weather drag and shift engagement time. Finally, by design, the disconnect function must be contained within both the PTU and RDU, which can pose challenges with packaging.

在断开和重新连接功能期间,AWD功能绝不能妥协。需要在车辆行驶时以及在ICE动力传动系统继续对前轴施加扭矩的同时,无缝断开和重新连接后驱动桥。最严峻的挑战是在AWD重新连接时的同步问题。这可能会因为狗离合器的阻塞换挡和换挡中断、与ICE/变速箱输出的后轮速度匹配、后驱动桥系统的惯性扭矩大、寒冷天气下的拖滞以及换挡接合时间而受到抑制。最后,从设计上讲,断开功能必须包含在PTU和RDU中,这可能带来包装方面的挑战。

Internal Combustion Engine Driveline

内燃机传动系统

4 AWD Disconnect – Transition to EV Drivetrains

4 全轮驱动断开 - 向电动汽车传动系统的过渡

The overall principle for AWD Disconnects is the same for electric vehicles as it is for ICE vehicles. When AWD is not needed, the disconnect system stops the secondary axle from rotating in order to reduce drag and improve efficiency. However, for EV systems the disconnect not only stops the drivetrain from rotating, but it also stops the electric motor from rotating. In the case of permanent magnet motors, this has the added advantage of allowing the eMotor to power off without backEMF issues.

AWD断开系统的总体原则对于电动汽车和内燃机(ICE)车辆是相同的。当不需要四轮驱动时,断开系统会停止第二个轴的旋转,以减少摩擦并提高效率。然而,对于EV系统来说,断开不仅阻止了传动系的旋转,而且还阻止了电动机的旋转。在永磁电机的情况下,这还有额外的优点,即允许eMotor在不产生反向电动势问题的情况下关闭电源。

Another key difference is that electric vehicles have a dedicated eMotor for each axle, or in some cases a dedicated eMotor for each wheel. This enables the eMotor to control the power and speed directly for each axle, and therefore it can also be used to manage the synchronization and speedmatching for the AWD disconnect & reconnect.

另一个关键区别是电动汽车为每个轴配备了一个专用的eMotor,或者在某些情况下为每个车轮配备一个专用eMotor。这使得eMotor能够直接控制每个轴的功率和速度,因此它还可以用于管理AWD断开与重新连接时的同步和速度匹配。

Another interesting comparison to illustrate the differences between the AWD ICE system and AWD EV system is that they “reconnect” in opposite ways. The ICE disconnect system uses the rear wheel rotation speed to synchronize and speed up the rear driveline to match the output speed of the ICE powertrain. In contrast, the EV disconnect system uses the powertrain (eMotor) output rotation to synchronize and speed up the rear driveline to match the rear wheel rotation speed.

另一个有趣的比较来说明AWD内燃机(ICE)系统和AWD电动汽车(EV)系统之间的差异是它们在重新连接时的相反方式。ICE断开系统使用后轮旋转速度来同步并加速后驱动轴以匹配ICE动力系统的输出速度。相比之下,EV断开系统使用动力总成(电动机)的输出旋转来同步和加速后驱动轴以匹配后轮旋转速度。

In summary, the advantages of EV AWD architecture is that there are dedicated motors for each axle that can control the speed and power and provide the disconnect synchronization. Additionally, the eMotor for the secondary axle can be com pletely powered off during disconnect mode. Because each axle has it’s own dedicated powertrain, the primary axle can also compensate for the secondary axle as it shifts to and from disconnect mode. All of this creates opportunity for new approaches to disconnect systems that cannot be accomplished with ICE AWD architectures.

总结来说,EV四轮驱动架构的优势在于每个轴都有专用的电机来控制速度和动力,并提供断开同步功能。此外,在断开模式下,次级轴的eMotor可以完全关闭电源。由于每个轴都有自己的专用传动系统,主轴可以在次级轴切换到和退出断开模式时进行补偿。所有这些都为无法通过ICE四轮驱动架构实现的断开系统的新方法提供了机会。

Transition to Batttery Electric Vehice Driveline

过渡到电池电动车辆驱动系统

5 Requirements for EV AWD Drivetrain Disconnects

5 电动汽车全轮驱动(AWD)传动系统断开要求

Requirements for EV AWD drivetrain disconnects include the following.

电动汽车全轮驱动传动系统断开的要求包括以下几点。

• Fast shift times, especially for the reconnect shift (<100 ms) • Reliable and repeatable shifts o No blocked shifts, ratcheting or synchronization issues • Smooth shifting. Note that EV systems do not mask NVH as compared to ICE systems. • System must be efficient in consideration of both vehicle system performance for optimized range and energy effi ciency of the shift actuation devices. • Manage disconnect for multiple operating modes: o eAWD Propulsion mode - forward torque o eAWD Coast mode – forward disconnect o eAWD Regen braking mode - reverse torque o eAWD Reverse drive mode - reverse torque • Flexible package locations for EV Drivetrains in locations between the eMotor and wheels.

快速换挡时间,尤其是重新连接换挡(<100毫秒)

可靠且可重复的换挡

无阻塞换挡、棘轮效应或同步问题

平顺换挡。注意,与内燃机系统相比,电动汽车系统不会掩盖NVH(噪声、振动和不平顺性)。

系统在考虑车辆系统性能以优化续航里程和换挡执行设备的能效方面必须是高效的。

管理多种工作模式的断开:

eAWD推进模式 - 正向扭矩

eAWD滑行模式 - 正向断开

eAWD再生制动模式 - 反向扭矩

eAWD倒车驱动模式 - 反向扭矩

在eMotor和车轮之间的位置为电动汽车传动系统提供灵活的包装位置。

New Production EV AWD Disconnect Solution

新生产EV四轮驱动断开解决方案

In 2021 Amsted Automotive (Means) launched its EV disconnect system on a battery electric adventure vehicle. The appli cation is a fourmotor system, with one motor and drive unit for each wheel. Two disconnect clutches are used simultane ously to disconnect the left and right motor/drive unit of the rear axle when AWD is not required. The disconnect system features a first production application of the Amsted’s electromagnetic actuation system, called the Dynamic Controllable Clutch (DCC). The DCC technology was first presented at CTi in 2018.

在2021年,Amsted汽车(梅恩斯)推出了其电动汽车断开系统,该系统应用于一款电池电动冒险车上。该应用是一个四电机系统,每个车轮都有一个电机和驱动单元。当不需要全轮驱动时,两个断开离合器会同时被用来断开后轴的左右电机/驱动单元。这个断开系统首次采用了Amsted的电磁驱动系统,称为动态可控离合器(DCC)。DCC技术最早在2018年的CTi展会上亮相。

The DCC is a firsttomarket innovation developed for the unique needs of electric vehicles. This new system leverages discrete electromagnetic actuation technology that can be utilized as an electric motor disconnect or as a shifting element in multispeed EV gearboxes looking to improve efficiency and improve packaging.

DCC是一种专为电动汽车独特需求而开发的首创创新技术。这种新型系统利用了离散电磁驱动技术,可以作为电动机断开装置,或者在寻求提高效率和改善封装的多速电动车变速箱中用作换挡元件。

The DCC electromagnetic technology has been combined with Amsted‘s mechanical diode clutch technology to create a new EV disconnect solution. A key advantage of the AWD disconnect technology is that it eliminates the possibility of a blocked shift and the shift interruption challenges associated with dog clutch systems.

DCC电磁技术与Amsted的机械二极管离合器技术相结合,创造了一种新的电动汽车断开解决方案。AWD断开技术的关键优势在于它消除了齿轮啮合系统可能出现的卡滞换挡和换挡中断挑战。

The DCC system offers fast and reliable shifting, with mechanical engagement always available for eMotor speed matching. This clutch can engage in less than 20 ms. The quality of the engagement is also very high, with no possibility of blocked shifts. There are no friction elements in the system, and it has a bistable magnetic latch (on/off) to eliminate power con sumption while instate – both of these characteristics maximize efficiency.

DCC系统提供快速可靠的换挡,机械啮合始终可用于电机速度匹配。这个离合器可以在不到20毫秒的时间内接合。接合的品质也非常高,没有可能发生阻塞的换挡。系统中没有任何摩擦元件,并且它具有双稳态磁性保持(开/关)以消除就位时的功耗——这两个特性最大化效率。

Mean’s Production Dynamic Disconnect Clutch

梅恩的生产动态断开离合器

6 Dynamic Controllable Clutch EV AWD Disconnect Performance

6 动态可控离合器电动汽车全轮驱动断开性能

Response Time • Full Travel Response Time: 17 ms • Electric Field Generation in Stator: 10.0 ms • Translator Movement / Strut Rise Time: 7.0 ms

响应时间

• 全行程响应时间:17毫秒

• 定子中电场生成:10.0毫秒

• 转换器移动/支柱上升时间:7.0毫秒

Energy Consumption • BiStable Magnetic latch for ON/OFF positions • No power consumption while instate • Magnetically latches in tooth butt even with power loss

能源消耗

• 双稳态磁性开关用于开/关位置

• 在状态内无功耗

• 即使在断电的情况下也能通过磁力锁在齿部

EaseofUse • No block or rejected shift are possible • Requires less control effort to synchronize state changes (On / Off)

易用性

• 不可能出现阻塞或拒绝的切换

• 同步状态变化(开/关)所需的控制力度更小

Torque • +2,800 Nm operating torque (8,000 Nm ultimate) • Torque can be scaled as needed • Enables safe sailing mode for primary axle. Primary axle sailing mode—no torque/coast.

扭矩

• 操作扭矩+2,800 Nm(极限扭矩8,000 Nm)

• 根据需要可调整扭矩

• 启用主轴安全航行模式。主轴航行模式——无扭矩/滑行。

7 NextGen EV Disconnect with OneWayClutch Functionality

7 下一代电动汽车断电开关,带单向离合器功能

In order to enable faster AWD vehicle system disconnect shift time, the next generation EV disconnect includes another Amsted Automotive innovation: integrated onewayclutch (OWC) functionality. This allows freewheeling in an overrun con dition for further reduction in energy consumption.

为了实现更快的全轮驱动(AWD)车辆系统断开换挡时间,下一代电动汽车断开装置包括了安斯特德汽车公司的另一项创新:集成了单向离合器(OWC)功能。这允许在空转条件下自由转动,从而进一步减少能量消耗。

The Bicycle Analogy: The disconnect with OWC can be compared to how a typical bicycle works. With power applied (pedaling), the onewayclutch (OWC) transmits torque to the wheel. When power is off (coasting and not pedaling), the onewayclutch (OWC) overruns or freewheels. When power is reapplied (pedaling again), the pedals ramps up to match the wheel speed and then transmits torque again to the wheel.

自行车类比:与OWC的断开连接可以类比为典型的自行车工作方式。施加动力(踩踏)时,单向离合器(OWC)将扭矩传递给车轮。当动力关闭(滑行且不踩踏)时,单向离合器(OWC)空转或自由轮。当重新施加动力(再次踩踏)时,脚踏板加速以匹配车轮速度,然后再次将扭矩传递给车轮。

Bicycle Analogy: Going from sailing mode, to bringing torque up to wheel speed by pedaling, then automatically transitioning to sailing by no longer applying torque to the bicycle pedal.

自行车类比:从航行模式开始,通过踩踏板将扭矩提高到车轮速度,然后自动过渡到航行状态,不再对自行车脚踏施加扭矩。

To manage both forward and reverse torque capability, Amsted Automotive developed a controllable bidirectional oneway clutch which enables a passive onewayclutch (OWC) in the forward direction and a controllable OWC in the reverse direc tion. In freewheel mode, both clutches are disengaged. During forward power mode, the passive onewayclutch (OWC) engages to transmit torque to the wheels. When Reverse or regenerative braking mode are required, the controllable OWC is engaged along with the forward passive OWC.

为了管理正向和反向扭矩能力,Amsted Automotive开发了一种可控的双向单向离合器,该离合器在正向方向上启用被动单向离合器(OWC),并在反向方向上启用可控的OWC。在空转模式下,两个离合器都处于分离状态。在正向动力模式下,被动单向离合器(OWC)接合以将扭矩传递到车轮。当需要倒车或再生制动模式时,可控OWC与正向被动OWC一起接合。

Means’ next generation Disconnect Clutch with added OneWay Clutch Overrunning Functionality

梅恩斯下一代带有单向超越离合器过载功能的断开离合器

To accomplish the integrated bidirectional OWC functionality, the forward power and forward disconnect modes are man aged with Amsted’s passive OWC technology. The controllable reverse torque for regeneration mode and Reverse gear is managed with Amsted’s controllable OWC technology. The actuation is accomplished with the DCC electromagnetic ac tuator. Combining these elements together provides a novel bidirectional OWC disconnect system based on existing and proven technologies.

为了实现集成双向OWC功能,正向功率和正向断开模式由Amsted的被动OWC技术管理。可控的反向扭矩用于再生模式和倒档,由Amsted的可控OWC技术管理。操作是通过DCC电磁执行器实现的。将这些元素结合起来,提供了一种基于现有和经过验证技术的创新双向OWC断开系统。

The application of this novel disconnect solution is enabled by new EV drivetrain architecture configurations together with Amsted’s mechanical diode onewayclutch (OWC) technology. This would not be possible for an ICE AWD architecture or without the controllable bidirectional OWC function.

这种新型断开解决方案的应用是由新的电动汽车传动系统架构配置以及Amsted的机械二极管单向离合器(OWC)技术所支持的。这对于内燃机全轮驱动架构或者没有可控的双向OWC功能来说是不可能的。

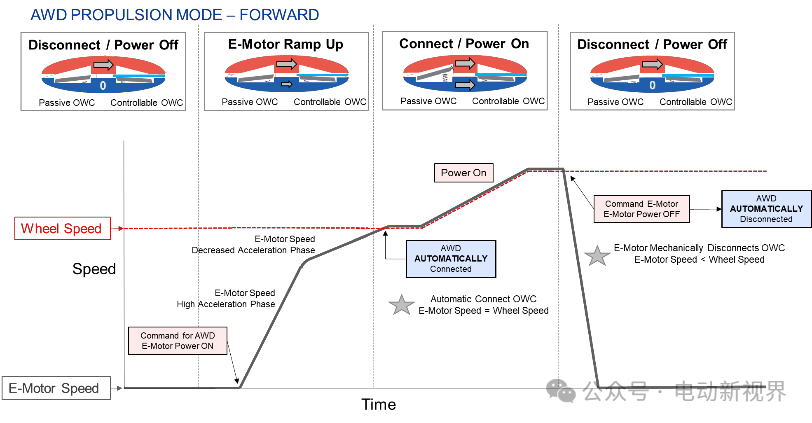

The following graphs illustrate how the technology can be utilized. In the forward propulsion direction, the disconnect and reconnect are automatic and is simply controlled by powering the propulsion motor on and off, just like described in the bicycle analogy. In the forward direction there is no synchronization required, because the passive OWC does not require an actuator. The shift time for disconnect/reconnect is only the time to ramp up or poweroff the propulsion motor. This automatic disconnect and reconnect capability provides industry leading disconnect system shift times.

以下图表说明了如何利用这项技术。在前进推进方向上,断开和重新连接是自动的,只需通过开启和关闭推进电机来控制,就像自行车类比中描述的那样。在正向方向上不需要同步,因为被动OWC(振荡水柱)不需要执行器。断开/重新连接的切换时间仅为启动或关闭推进电机的上升时间。这种自动断开和重新连接能力提供了行业领先的断开系统切换时间。

For the reverse direction, the controllable OWC shift time is 17 milliseconds for Reverse and regenerative braking. In both the regenerative and Reverse modes, the controllable reverse OWC can be prestaged and ready to transfer reverse torque when commanded. The system is based on proven production technology and is reliable. It eliminates the possibility of blocked shifts or rejected shifts. Mechanical engagement is always available for speed matching the eMotor. It offers the opportunity for flexible EV drivetrain packaging locations by providing modular style and integrated solutions. And it can improve the efficiency of AWD EVs by as much as 5% on the highway because there are no friction elements and the magnetic latching for on/off states doesn’t require any power consumption to remain in state.

对于反向方向,可控制的OWC换挡时间为17毫秒,适用于倒车和再生制动。在再生和倒车模式下,可控的反向OWC可以预先设置并准备好转移反向扭矩,只要接到命令即可。该系统基于经过验证的生产技术,可靠性强。它消除了换挡受阻或拒绝换挡的可能性。机械啮合始终可用于匹配电动机的速度。它提供了灵活的电动汽车传动系统包装位置的机会,通过提供模块化样式和集成解决方案。由于没有摩擦元件,并且磁性锁定状态不需要任何功耗来保持状态,因此它可以提高AWD EV的高速效率高达5%。

Forward Torque Functional Sequence

正向扭矩功能顺序

Reverse and Regen Functional Sequence

逆转和再生功能序列

8 Example Use Case: Differential Disconnect with Integrated OneWayClutch

8 示例用例:集成单向离合器的差动断开

An example of flexible packaging is the Differential Disconnect with Integrated BiDirectional OWC. This use case enables further drivetrain system integration for improved packaging, reduced mass and cost of the eAxle system. In this centralized location, both wheels of the axle can be disconnected with a single clutch system as compared to a separated disconnect clutch for each wheel. This design is currently in hardware development.

一个灵活包装的例子是集成双向OWC的分立断开装置。这种用例可以实现进一步的车身系统集成,以改善包装、减少e轴系统的质量和成本。在这个集中的位置,两个轮子都可以通过单个离合器系统断开连接,而不是每个轮子的分离断开离合器。该设计目前正处于硬件开发阶段。

An additional feature is the unique capability to netform complex and large diameter product geometries through Amsted Automotive’s Advanced Metal forming businesses. This allows for a more compact design with increased torque density through vertical integration.

通过Amsted Automotive的高级金属成型业务,独特的净成形能力可以实现复杂和大直径产品几何形状的成型。这使得设计更加紧凑,并通过垂直整合提高了扭矩密度。

Differential Integrated Overrunning Disconnect

差动集成过载断开

Means’ next generation Disconnect Clutch with added OneWay Clutch Overrunning Functionality

梅恩斯的下一代断开离合器,增加了单向离合器的过载功能

9 Summary / Conclusion

9 摘要/结论

The AWD Disconnect with integrated & BiDirectional OWC offers unique solutions and new building blocks for Electric Vehicle Drivetrain designs. The notable benefits of this clutch are as follows:

AWD断开装置与集成的双向OWC提供了独特的解决方案和新构建模块,用于电动汽车传动系统设计。这个离合器的显著优点如下:

Requirements Addressed for EV AWD Disconnects

电动汽车全轮驱动断开要求

• Faster system response & shift times: ➢ Automatic OWC disconnect shift – forward propulsion. eMotor control is used to connect the EDU. ➢ The time to synchronize, stabilize, and verify before torque transfer can all be reduced or removed. ➢ 17 ms preengagement shift - reverse / regen direction

更快的系统响应和换挡时间:

• 自动OWC断开换挡 - 正向推进。使用eMotor控制连接EDU。

• 在扭矩传递之前同步、稳定和验证的时间都可以减少或消除。

• 17毫秒预接合换挡 - 倒车/再生方向

• Reliable: ➢ No blocked shifts or ratcheting (unblocked passive engagement) ➢ Based on proven production technology (building blocks)

可靠:➢ 无阻塞的换挡或棘轮效应(无障碍被动啮合) ➢ 基于经过验证的生产技术(构建模块)

• Smooth shifting: managed with eMotor controls ➢ Mechanical engagement always available for eMotor speed matching

• 平顺换挡:通过eMotor控制实现 ➢ 机械结合始终可用于匹配eMotor速度

• Efficiency: can improve eAWD highway efficiency by 5% ➢ Mechanical Engagement - No friction elements ➢ BiStable Magnetic latch (on/off) - No power consumption while instate

效率:可以提高eAWD公路效率5% ➢ 机械啮合 - 无摩擦元件 ➢ 双稳态磁性夹持器(开/关)- 在状态时无功耗

• Flexible package locations for EV Drivetrains

电动汽车驱动系统的灵活包装位置

• Provides 4 Operational Modes:

提供4种操作模式:

1. eAWD Propulsion - forward torque

eAWD 推进系统 - 前轮扭矩

2. eAWD Disconnect - coast “freewheel”

eAWD断开 - 滑行“自由轮”

3. eAWD Regen Braking - reverse torque

eAWD再生制动 - 反向扭矩

4. eAWD Reverse Gear - reverse torque

eAWD倒车齿轮 - 倒车扭矩

Additional System Opportunities & Benefits

附加系统机会与好处

• Simplified Controls Requirements:

简化控制要求:

➢ Controlling propulsion motor automatically connects or disconnects axle via OWC.

控制推进电机通过OWC自动连接或断开轴。

➢ No need to control a shift actuator for disconnect/reconnect in the forward direction.

无需控制换挡执行器以在正向方向上断开/重新连接。

➢ Simplified system controls & reduce failure modes compared to traditional dog clutch

简化系统控制和减少与传统爪式离合器相比的故障模式。

• Enable safe sailing mode for primary axle

启用主轴安全航行模式

➢ Primary axle Sailing mode – no torque / coast

主轴航海模式 - 无扭矩/滑行

10 Further Considerations

The integrated onewayclutch (OWC) and controllable bidirectional OWC technologies can be utilized for multifunctional applications. The following are examples, including some that are now under development.

10 进一步考虑

集成的单向离合器(OWC)和可控双向OWC技术可用于多功能应用。以下是一些例子,包括现在正在开发的一些。

• AWD Disconnect with rotating input and output. • AWD Disconnect grounded to a housing, especially for coaxial or planetary drivetrain configurations. • AWD Disconnect combined with parklock function. • Primary axle disconnect for EV sailing mode. • Power shift 2speed and multispeed shift systems. • Shift system with integrated disconnect. • Shift system with integrated parklock.

• 具有旋转输入和输出的全轮驱动断开装置。

• 全轮驱动断开接地到外壳上,特别是用于同轴或行星传动配置。

• 结合了驻车锁功能的全轮驱动断开。

• 电动汽车滑行模式的主轴断开。

• 两速和多速换挡系统。

• 集成断开的换挡系统。

• 集成驻车锁的换挡系统。

Shift systems with integrated onewayclutches (OWC) to enable smooth shift transitions will be the subject of a future presentation.

带有集成单向离合器(OWC)的换挡系统,以实现平滑的换挡过渡,将是未来演讲的主题。