利用MatDEM分析TBM刀盘引起的岩石碎裂-同济大学

论文题目

研究内容

The study of rock fragmentation mechanism significantly contributes to the advancing speed of tunnel boring machines (TBMs). In this sense, numerous factors are shaping the rock fragmentation mechanism of their disccutters. Among them, rock structural parameters, such as joint inclination, orientation, spacing, etc., considerably impact cutting force as well as rock-cutting process. However, detailed relationships between rock-cutting parameters and rock mass ones have not been to date proven, and rock fragmentation mechanism still needs to be investigated in depth.

In this paper, a three-dimensional (3D) discrete element model of rock-cutting using a disccutter was established via the high-performance MatDEM software. To simulate the fragmentation performance of the rock undergoing the impact load, an elastic–plastic contact model was firstly proposed based on the linear elastic contact model, verified by several mechanical experiments. Then, the influence of different joint parameters (e.g., joint inclination, orientation, spacing, etc.) on cutting force and rock fragmentation volume was examined. At the same time, the effect of joint parameters on specific energy (SE) was calculated to explore the joint influence on rock-cutting efficiency.

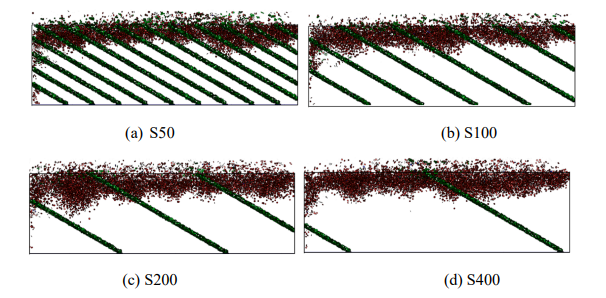

The simulation results show that the elastic–plastic contact model can better simulate the plastic deformation characteristics of the brittle rock, and the improved model can imitate the generation of the rock fragment structure. As well, the influence of the joint orientation and spacing on the mean value of the cutting force and the rock fragmentation volume is obvious, and the propagation mode of the internal cracks in the rock varies with reference to the joint orientation. The existence of the joints also decreases the rock-cutting SE, and consequently the rock-cutting efficiency can reach the highest level when the joint spacing is equal to 50 mm and the joint orientation is about 30◦. The opposite inclination of the joint correspondingly leads to the opposite change in the rock-cutting parameters, which can be eliminated through rotating cutting in practice. This study explores the influence of joint parameters on rock-cutting ones and reveals crack distribution mechanism in jointed rock mass.

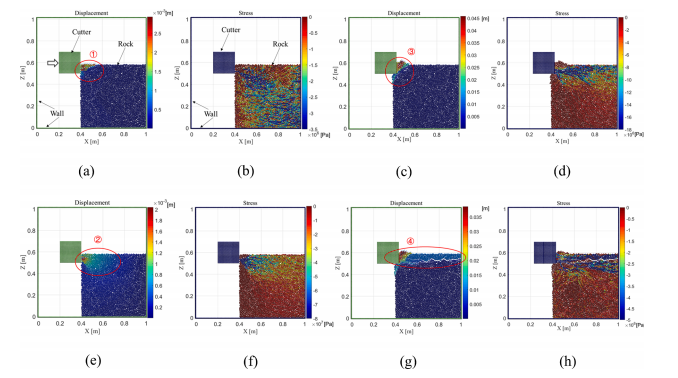

Figure 5:Rock displacement and stress distribution. Linear elastic model.

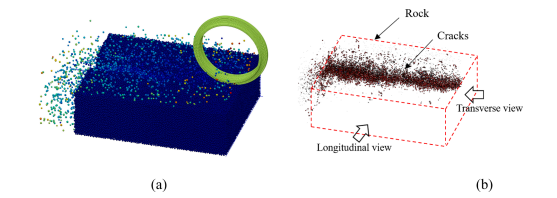

Figure 10: Rock-cutting process (a) displacement of particles and (b) crack distribution.

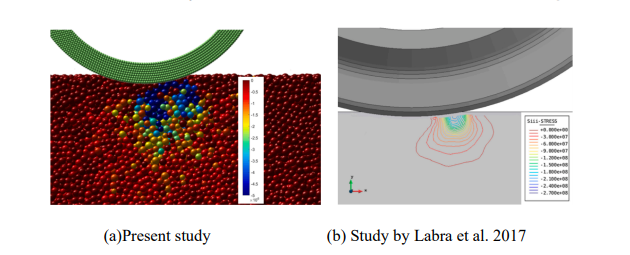

Figure 12:Rock stress distribution.

了解详情

Yadong Xue, Jie Zhou, Chun Liu,et al.Rock fragmentation induced by a TBM disc-cutter considering the effects of joints: A numerical simulation by DEM[J].

Computers and Geotechnics,Volume 136,2021,104230,ISSN 0266-352X,