ANSYS APDL | 橡胶筒的超弹性挤压

问题描述

理论模型

|

有限元模型

|

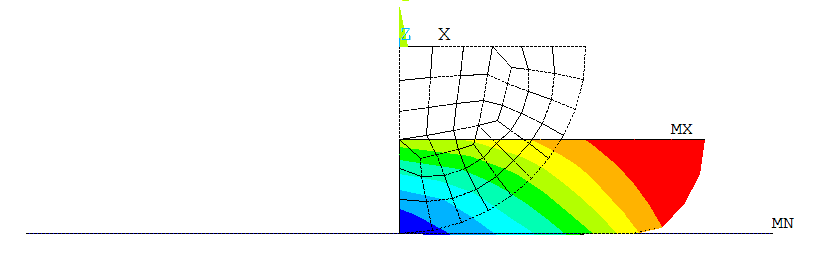

压缩后变形云图

|

采用单元包括plane182平面单元、Targe169和Conta171接触单元,读者可以自行将plane182单元换成plane183、solid185、solid186单元,或者Conta171分别换成Conta172、Cont173、Cont174单元进行尝试。分析一些这几种单元对计算收敛性的影响及结果的影响。

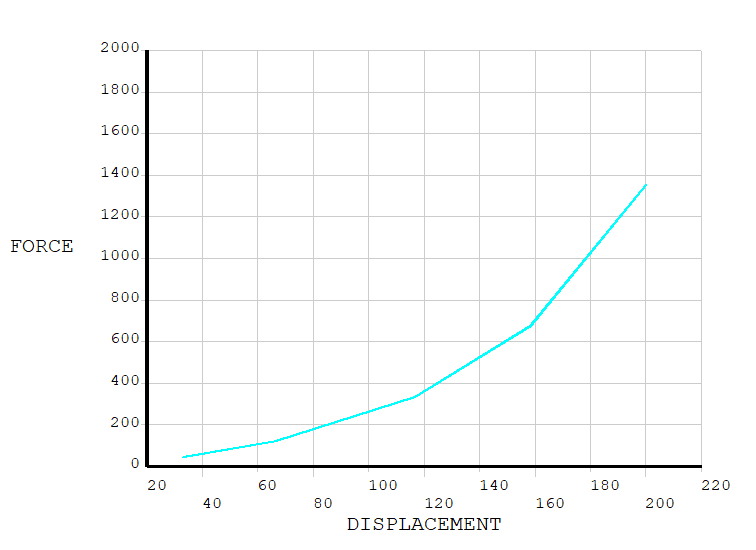

最终得到的力位移曲线如下,可以看到该变形过程是一个硬化的变形过程。

命令流解读

单元定义,注意u-P混合公式法的运用是具有一些其他前提条件的,比如说该方法只能用稀疏矩阵求解器或者波前求解器。

ET,1,PLANE182, , ,2 ! 2-D PLANE-STRAIN 4-NODE STRUCTURAL SOLIDKEYOPT,1,6,1 ! 打开u-P混合公式法ET,2,TARGE169 ! 2-D TARGET ELEMENTET,3,CONTA171 ! 2-D CONTACT ELEMENTKEYOPT,3,5,4KEYOPT,3,10,1

材料定义,超弹性材料采用常用的mooney本构。

MP,EX,1,2.82 ! YOUNG'S MODULUS [MPA]MP,NUXY,1,0.49967 ! POISSON'S RATIOC10 = 0.293C01 = 0.177NU1 = 0.49967DD = 2*(1-2*NU1)/(C10+C01)TB,HYPER,1,1,2,MOONEYTBDATA,1,C10,C01,DD

刚性接触面直接用TSHAP命令生成刚性线即可。

TSHAPE,LINE完成的命令流如下,读者自取:

FINISH/CLEAR/PREP7!关闭智能网格大小VM211, RUBBER CYLINDER PRESSED BETWEEN TWO PLATES, ,2 ! 2-D PLANE-STRAIN 4-NODE STRUCTURAL SOLID! Mixed U-P FORMULATION! 2-D TARGET ELEMENT! 2-D CONTACT ELEMENTKEYOPT,3,5,4KEYOPT,3,10,1! YOUNG'S MODULUS [MPA]! POISSON'S RATIOC10 = 0.293C01 = 0.177NU1 = 0.49967DD = 2*(1-2*NU1)/(C10+C01)TB,HYPER,1,1,2,MOONEYTBDATA,1,C10,C01,DDR = 200 ! RADIUS OF CYLINDER (mm)! SWITCH TO CYLINDRICAL C.S.! DEFINE KEYPOINTSK,2,R,-90K,3,RK,4,(0.5*R),-90K,5,(0.6*R),-45K,6,(0.5*R)K,7,R,-45L,2,7L,7,3! SWITCH TO CARTESIAN C.S.A,2,7,5,4A,7,3,6,5A,4,5,6,1TSHAPE,LINEK,1001,-2*R,-RK,1002,2*R,-RL,1002,1001! SAVE MODEL FOR SECOND ANALYSISTYPE,1! MESH ALL AREASREAL,2TYPE,2LMESH,10LSEL,S,LINE,,1,2,1TYPE,3LMESH,ALLsave,cont171,dbFINI! MACRO TO SOLVE MODEL/SOLU!SOLCONTROL,0ANTYPE,STATICNSEL,S,LOC,XD,ALL,UXNSEL,S,LOC,YCP,1,UY,ALL*GET,NCEN,NODE,,NUM,MINALLSEL!CNVTOL,F,,,,-1! INCLUDE LARGE DEFORMATION EFFECTS! SPECIFY NUMBER OF SUBSTEPS IN LOAD STEP! WRITE SOLUTION FOR EVERY SUBSTEP! APPLY DISPLACEMENT UY = -100 TO COUPLED NODES!NROPT,FULL,,OFFSOLVEFINISH*ENDSOLV2D ! USE MACRO SOLVE2D! MACRO FOR POST-PROCESSING/POST1!真实变形显示! 变形结果和未变形结果显示FINISH/POST26/AXLAB,Y,FORCE/AXLAB,X,DISPLACEMENTNSOL,2,NCEN,U,YRFORCE,3,NCEN,F,YPROD,2,2,,,,,,-2PROD,3,3,,,,,,-2XVAR,2! PLOT DISPLACEMENT VS FORCE! PRINT DISPLACEMENT, FORCE!*GET,F1,VARI,3,RTIME,.5!*GET,F2,VARI,3,RTIME,1!*DIM,LABEL,CHAR,2,2!*DIM,VALUE,,2,3!LABEL(1,1) = 'F (N) @ ','F (N) @ '!LABEL(1,2) = '.1','.2'!*VFILL,VALUE(1,1),DATA,250,1400!*VFILL,VALUE(1,2),DATA,F1,F2!*VFILL,VALUE(1,3),DATA,ABS(F1/250),ABS(F2/1400)FINISH*ENDPLOTS ! USE MACRO PLOTS

注:该案例参考来源于ANSYS帮助文件中验证案例vm211。

全文结束,感谢阅读。

登录后免费查看全文

著作权归作者所有,欢迎分享,未经许可,不得转载

首次发布时间:2023-09-26

最近编辑:1年前

还没有评论

相关推荐

最新文章

热门文章