Joint2D节点单元使用经验分享

00

引言

Introduction

诸多震害现象表明,结构设计不当时,结构节点域具有先于构件破坏的可能,甚着将引起结构倒塌等灾害。结构设计中,《混凝土结构设计规范》、《建筑抗震设计规范》等通过节点剪力增大系数、受剪水平截面要求等措施来实现“强节点、弱构件”的抗震需求。然而科研中更多面向新型的构件和结构体系的研究分析,采用规范的设计方法,并不能保证该结构体破坏均发生于节点域之外,在数值模拟中将节点区视为刚域的处理方法,将可能高估结构体系的抗震性能,引起安全隐患。结构分析中是有必要对节点区域采用相应的节点单元来更加合理的预估结构体系的性能。

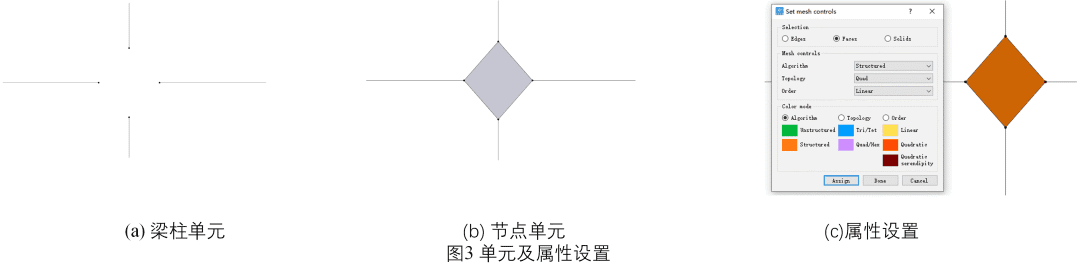

Lowes and Altoontash提出了“超级节点单元”来考虑节点区的弹塑性发展,并于在OpenSEES中嵌入了相应的节点单元“BeamColumnJoint Element”。Altoontash在“BeamColumnJoint Element”的基础上做了简化,将考虑钢筋黏结滑移的弹簧单元修改为转动弹簧,模型应用更为方便,提出了“Joint2D”单元,同样嵌入了OpenSEES中。然而在采用命令流编写结构模型时,一个节点的处要额外创建4个节点,如图所示,以计算节点中剪切板的特性。而面对结构体系中少则几十,多则上百成千的节点,虽然理论可行,但整个结构体系处理下来的工作量是非常大的,非常不便。

一致。

01

建模方法介绍

Introduction of modeling

STKO作为OpenSEES前后处理的软件,具有非常强大的批量化、参数化建模能力,尤其在创建节点单元这样的重复性高,但节点编码复杂的单元时,展现了无与伦比的简洁性。在此就STKO中创建节点单元的步骤做简单介绍。

在此以“BeamColumnJoint Element”为例进行介绍:

1)几何模型建立

①因为BeamColumnJoint中间有剪切板,剪切板代表节点区实际尺寸,四边与梁柱相连,建立梁柱单元时,单元长度按实际尺寸取,如梁取净跨,柱取净高。

②在梁柱的4个节点之间采用面单元。

③在mesh controls里面设置属性时,Algorithm设置为Structured;Topology设置为Quad;Order设置为Linear。

2)单元属性

①建议采用pingching4材料模型,创建节点单元剪切板的本构关系,本构关系的中的特征参数则可采用collions等提出修正压力场理论(MCFT)计算,滞回规则可采用Parkand Ang提出的损伤指标来确定。需要注意的是,剪切板所采用的剪切本构关系在单元的应用中要转化为转角和弯矩的关系。

②建议采用Bar-slip材料模型模拟钢筋的黏结滑移。如果采用Joint2D单元,核心剪切板和考虑钢筋黏结滑移的弹簧单元均可采用pingching4材料模型实现。

02

使用感受和建议

Suggestions on STKO

1)STKO采用三角形的图案处理,容易让人产生错觉,以为是节点构造上的一种创新形式。如果能采用矩形来代替菱形,会有更好的建模观感。

2)后处理程序中,从Volumne、Gauss Point、Beam/Fiber里缺乏节点的相应输出,如节点的剪切应变,单元应力等。不容易通过变形程度来判断节点先发生破坏还是塑性铰区先发生破坏。建议设置节点区转角、应变、剪切应力、节点损伤的输出参数。

3)加入节点单元的结构体系计算用时量远超无节点单元结构体系,并且采用节点单元的结构体系不能采用OpenseesSP并行运算,导致计算模型费时太长。是否可以像Asdea软件公司开发ASDConcrete3D材料一样,开发一个集成节点单元,更加方便使用。

附件:节点单元参数含义

BeamColumnJoint Element element beamcolumnjoint $eleTag $Nd1 $Nd2 $Nd3 $Nd4 $Mat1 $Mat2 $Mat3 $Mat4 $Mat5 $Mat6 $Mat7 $Mat8 $Mat9 $Mat10 $Mat11 $Mat12 $Mat13 <$eleHeightFac $eleWidthFac> $Tag unique element object tag $Nd1 $Nd2 $Nd3 $Nd4 four nodes $Mat1 uniaxial material tag for left bar-slip spring at node 1 $Mat2 uniaxial material tag for right bar-slip spring at node 1 $Mat3 uniaxial material tag for interface-shear spring at node 1 $Mat4 uniaxial material tag for lower bar-slip spring at node 2 $Mat5 uniaxial material tag for upper bar-slip spring at node 2 $Mat6 uniaxial material tag for interface-shear spring at node 2 $Mat7 uniaxial material tag for left bar-slip spring at node 3 $Mat8 uniaxial material tag for right bar-slip spring at node 3 $Mat9 uniaxial material tag for interface-shear spring at node 3 $Mat10uniaxial material tag for lower bar-slip spring at node 4 $Mat11uniaxial material tag for upper bar-slip spring at node 4 $Mat12uniaxial material tag for interface-shear spring at node 4 $Mat13uniaxial material tag for shear-panel $eleHeightFacfloating point value (as a ratio to the total height of the element) to be considered for determination of the distance in between the tension-compression couples (optional, default: 1.0) $eleWidthFac floating point value (as a ratio to the total width of the element) to be considered for determination of the distance in between the tension-compression couples (optional, default: 1.0) |

Joint2D Element $eleTagunique element object tag $Nd1 $Nd2 $Nd3 $Nd4integer tags indicating four external nodes where the joint element is connected to the adjoining beam-column element $NdC integer tags indicating the central node of beam-column joint (the tag is used to generate the internal node, thus, the node should not exist in the domain or be used by any other node) $Mat1 uniaxial material tag for interface rotational spring at node 1. Use a zero tag to indicate the case that a beam-column element is rigidly framed to the joint. (optional) $Mat2 uniaxial material tag for interface rotational spring at node 2. Use a zero tag to indicate the case that a beam-column element is rigidly framed to the joint. (optional) $Mat3 uniaxial material tag for interface rotational spring at node 3. Use a zero tag to indicate the case that a beam-column element is rigidly framed to the joint. (optional) $Mat4 uniaxial material tag for interface rotational spring at node 4. Use a zero tag to indicate the case that a beam-column element is rigidly framed to the joint. (optional) $MatCuniaxial material tag for rotational spring of the central node that describes shear panel behavior $LrgDspTag an integer indicating the flag for considering large deformations: 0 - for small deformations and constant geometry 1 - for large deformations and time varying geometry 2 - for large deformations ,time varying geometry and length correction |

来源:xinchenxuan828