Modelling and Simulation Testing of Main Bearing Loads and Strains in Crankshafts Caused by Deviations in the Position of the Shaft Journal and Bearing Axes

doi:10.2478/mape-2020-0004

Date of submission to the Editor: 03/2020

Date of acceptance by the Editor: 06/2020

MAPE 2020, volume 3, issue 1, pp. 41-56

Krzysztof Nozdrzykowski

ORCID ID: 0000-0003-2785-0868

Zenon Grządziel

ORCID ID: 0000-0001-9348-1111

Maritime University of Szczecin, Poland

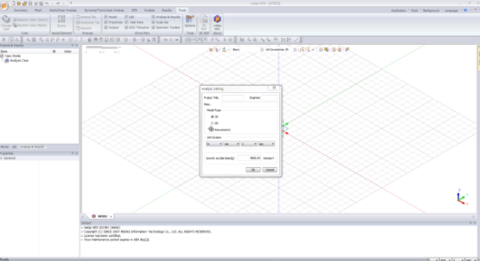

Crankshafts of a ship’s main propulsion power machines as well as auxiliary engines are one of the most important elements of the crank-piston system, and perform rotary movement supported by bearings in the engine block. Sliding bearings are commonly used in this type of design, currently, most often fitted with the so called flexible multilayer thin-walled bushings. The use of this type of bearings is dictated by a number of proven and unquestionable advantages of thin-walled bushings over traditional solutions such as rigid thick-walled bushings. To some extent, they maintain their shape and dimensions, regardless of the housing in which they are mounted. Exclusive use of flexible bushings in railway and marine engines is characterized by the fact that their flexible design is unable to provide the appropriate rigidity and geometric shape of the bearing, and hence, these functions are facilitated by the bearing socket. The thickness of the flexible bushings must be within close tolerances to ensure the required clearance value in relation to the journal and the exact circumferential length, which results in its compression into the socket. This pressure should guarantee the appropriate values of radial surface pressures and, as a result the friction forces at the contact between the bushings and the socket should ensure its rotation in the socket. Regardless of the design of the bushings, the most important dimension determining the correct functioning of the crank-piston system for shaft bearing is the bearing clearance (Łukomski,1972; Kozłowiecki, 1974; Basiński and Szyndler, 1984; Barwell, 1984).In most of the available studies concerning the analysis of factors influencing the change in the practical value of bearing clearance, the impact of geometrical deviations of the bearing system (especially crankshafts) is marginalized. The measuring techniques currently in use lack the equipment and instruments to accurately assess the geometric condition of crankshafts. Therefore, such measurements are usually carried out with the use of conventional measuring equipment, the accuracy of which is not adjustable in accordance with the manufactured shafts. The measurement system enabling a correct and comprehensive assessment of the geometric condition of large-size crankshafts has been developed in the Cathedral of Basic Engineering and Materials Science of the Maritime University of Szczecin. This system is equipped with a flexible support system for the measured object, compensating the elastic deformations of the shaft due to its own weight; whereby the measurements of large-size crankshafts can be carried out in conditions corresponding to the non-reference measurements when determining the object measured in counterpoints (Nozdrzykowski, 2013;Nozdrzykowski, 2017; Nozdrzykowski, 2015; Nozdrzykowski, 2011a;Nozdrzykowski, 2011b).Fig. 1 shows a constructed test rig operating according to the adopted concept of the measuring system, equipped with a flexible support system for the measured object.Source: prepared by the authors

The authors have conducted a number of studies justifying the purposefulness and necessity to measure both the shape and positional deviations of the crankshaft journals axes, for which the proposed measurement system has proved to be entirely relevant. The research results are presented subsequently.

MATCHING THE BEARING CLEARANCE EXAMPLES OF CALCULATIONS

Plain bearing clearance, as previously highlighted, is one of the most important factors determining its operation, especially in the case of hydrodynamic lubrication. The clearance distribution depends on the difference between journal and socket diameters and deviations in shape. Numerous experimental and theoretical works have shown that a change in bearing clearance causes a change in all parameters for bearing operation. Given the complexity of the issue and the challenge of taking into account all the factors influencing the thickness of the lubricant layer under actual operating conditions, the theoretical evaluation of the optimum clearance is not always precise. It is important to take into account the presumed bearing load capacity, the minimum thickness of the lubricant layer, the lubricant flow and operating temperature as well as the journal and bushings sliding layer materials when analyzing the clearance matching. The theoretical basis for this was developed by Glӓser and Gnilke (Kozłowiecki, 1974). A more precise selection of bearing clearance values allows to obtain various empirical or semi-empirical formulas, tables and diagrams related to the state during bearing operation (operating clearance) or to the conditions during assembly (mounting clearance). The knowledge of the working clearance is essential for calculating the plain bearing. Moreover, knowledge of the mounting clearance together with appropriate tolerances is essential for the correct manufacturing and assembly of a bearing. A pragmatic formula for optimal matching of bearing clearance for sliding bearings of fast and medium-speed internal combustion engines, according to Glacier Co United Kingdom (Kozłowiecki, 1974):

For the other types of motors, the clearance should be determined according to the formula:Kingsbury (Kozłowiecki, 1974), gives a less complex relation which allows the selection of bearing clearance in diameter, depending solely on the journal diameter:Recommended clearance values are quite often expressed in relative form (most often in relation to the journal diameter). Such form is preferred by Vogelpoll (Kozłowiecki, 1974), making the selection of the working value of relative bearing clearance dependent on the journal circumferential speed. It is expressed as a function:The relative form of the recommended clearance value is also given by Willi and Kamps (Kozłowiecki, 1974).In the case of Willi and Kamps, the relative clearance value is determined by the sliding layer material:– for a sliding layer made of white material adopt

For the other types of motors, the clearance should be determined according to the formula:Kingsbury (Kozłowiecki, 1974), gives a less complex relation which allows the selection of bearing clearance in diameter, depending solely on the journal diameter:Recommended clearance values are quite often expressed in relative form (most often in relation to the journal diameter). Such form is preferred by Vogelpoll (Kozłowiecki, 1974), making the selection of the working value of relative bearing clearance dependent on the journal circumferential speed. It is expressed as a function:The relative form of the recommended clearance value is also given by Willi and Kamps (Kozłowiecki, 1974).In the case of Willi and Kamps, the relative clearance value is determined by the sliding layer material:– for a sliding layer made of white material adopt  = 0.0005,According to the presented recommendations given in the available source materials, the clearance values and the mounting clearance tolerances (boundary clearances) may vary considerably depending on the interpretation.Therefore, the proposal of Milowiza is advantageous in establishing clearance limits. It is recommended that mounting clearance should be accepted within the boundaries:From a geometric point of view, the minimum "cold" clearance is determined structurally by means of an appropriate selection of the journal dimensions and dimensional deviations, the socket diameter and the thickness of the bushings, and the increase in the socket diameter caused by the compression.INFLUENCE OF GEOMETRICAL DEVIATIONS ON THE BEARINGCLEARANCE DISTRIBUTIONThe aforementioned crankshaft, for which exemplary calculations of the recommended clearance values have been made (Table 1), is the object under investigation. The aim of the research was to verify and implement an innovative measurement system with the so-called flexible support of the measured object, developed at the Maritime Academy in Szczecin. The system enables, as previously highlighted, measurements of geometric deviations of large-size crankshafts in conditions corresponding to the non-reference measurements determining the shaft measured in counterpoints.The difference between a real bearing and an ideal bearing is defined as the interaction of two ideal cylinders that can be very large in reality where the geometry of the lubrication space of both bearings is compared. The journal, socket and bushing can have different regular or irregular shape contours in both transverse and longitudinal cross-sections. The axes of the individual shaft journals and sockets can be diagonally positioned in relation to each other as a result of machining errors, wear, and elastic or thermal deformation caused by operating conditions. Due to these errors, the actual minimum thickness of thelubricating film can often be less than the minimum calculated under the assumption of perfect shapes and concentricity. Fig. 2 illustrates the complexity of the geometry of the bearing clearance space when only the single crankshaft plain bearing is considered. One of the possible shape and axis error position of the components forming a single sliding bearing with the so-called flaccid thinwalled bushings is shown in Fig. 2 in the longitudinal and transverse crosssection.Based on the thin bearing theory, a correlation can be derived to determine the maximum allowable misalignment of the journal and pans mounted in the socket (Barwell, 1984).Equation (6) applies when a bearing with misalignment is under investigation during operation. The practical application of this equation is illustrated in Fig. 3.In case of ideal concentricity shown in Fig. 3a:Taking into account, the probability of coaxial misalignment, the axes of the journal and the pan hole can take the reciprocal position as in the Fig. 3b. The coaxial misalignment defined by angle can then be expressed by the following equation:disappears and consequently the shaft comes into contact with the bushing at its edge. Thus, the possibility of running the transverse sliding bearings under conditions where the geometric size of the shaft journal axis and pan hole is disturbed is significantly reduced. Following equation (6) there is no benefit in increasing clearance when λ reaches 0.78, in this case the allowable misalignment is given by the relation (Barwell, 1984):

= 0.0005,According to the presented recommendations given in the available source materials, the clearance values and the mounting clearance tolerances (boundary clearances) may vary considerably depending on the interpretation.Therefore, the proposal of Milowiza is advantageous in establishing clearance limits. It is recommended that mounting clearance should be accepted within the boundaries:From a geometric point of view, the minimum "cold" clearance is determined structurally by means of an appropriate selection of the journal dimensions and dimensional deviations, the socket diameter and the thickness of the bushings, and the increase in the socket diameter caused by the compression.INFLUENCE OF GEOMETRICAL DEVIATIONS ON THE BEARINGCLEARANCE DISTRIBUTIONThe aforementioned crankshaft, for which exemplary calculations of the recommended clearance values have been made (Table 1), is the object under investigation. The aim of the research was to verify and implement an innovative measurement system with the so-called flexible support of the measured object, developed at the Maritime Academy in Szczecin. The system enables, as previously highlighted, measurements of geometric deviations of large-size crankshafts in conditions corresponding to the non-reference measurements determining the shaft measured in counterpoints.The difference between a real bearing and an ideal bearing is defined as the interaction of two ideal cylinders that can be very large in reality where the geometry of the lubrication space of both bearings is compared. The journal, socket and bushing can have different regular or irregular shape contours in both transverse and longitudinal cross-sections. The axes of the individual shaft journals and sockets can be diagonally positioned in relation to each other as a result of machining errors, wear, and elastic or thermal deformation caused by operating conditions. Due to these errors, the actual minimum thickness of thelubricating film can often be less than the minimum calculated under the assumption of perfect shapes and concentricity. Fig. 2 illustrates the complexity of the geometry of the bearing clearance space when only the single crankshaft plain bearing is considered. One of the possible shape and axis error position of the components forming a single sliding bearing with the so-called flaccid thinwalled bushings is shown in Fig. 2 in the longitudinal and transverse crosssection.Based on the thin bearing theory, a correlation can be derived to determine the maximum allowable misalignment of the journal and pans mounted in the socket (Barwell, 1984).Equation (6) applies when a bearing with misalignment is under investigation during operation. The practical application of this equation is illustrated in Fig. 3.In case of ideal concentricity shown in Fig. 3a:Taking into account, the probability of coaxial misalignment, the axes of the journal and the pan hole can take the reciprocal position as in the Fig. 3b. The coaxial misalignment defined by angle can then be expressed by the following equation:disappears and consequently the shaft comes into contact with the bushing at its edge. Thus, the possibility of running the transverse sliding bearings under conditions where the geometric size of the shaft journal axis and pan hole is disturbed is significantly reduced. Following equation (6) there is no benefit in increasing clearance when λ reaches 0.78, in this case the allowable misalignment is given by the relation (Barwell, 1984): The case of eccentricity of the elements forming the sliding bearing shown in Fig. 3b describes a journal as an ideal cylinder whose axis is non-deformable.Due to the interconnection and interaction of the interlinked, individual crankshafts are deformed differently, and the journal axes also undergoes a variety of bends and torsional elastic deformations. Consequently, this leads not only to a change in clearance but also to rapid, dynamic changes in the value of reaction forces in the bearings during shaft rotation. These observations are confirmed by the results of simulation tests carried out to assess the influenceof geometrical deviations of the bearing system upon the values of main bearing loads and strains in crankshafts.MODELING AND SIMULATION RESEARCH CONCERNING THEINFLUENCE OF GEOMETRICAL DEVIATIONS OF THE BEARING SYSTEMON THE VALUES OF MAIN BEARING LOADS AND STRAINS INSimulation tests were carried out using the Midas NFX 2019 simulation program based on FEM. The aforementioned crankshaft of the medium-rotation mainBuckau Wolf R8DV 136 engine of the vessel was modeled. The crankshaft was 3630 mm long and 9280 N heavy, with ten 149 mm diameter main journals and eight 144mm diameter crank journals, Fig. 4.Analysis of deformations and reaction forces, with consideration of therecommended clearance value and shaft weight in relation to the assumed inaccuracies with regard to the position of journal and socket axes of individual main bearings, was made for subsequent angular shaft positions, in the range of 0°-360°, changing its position every 15°. Simulation tests were conducted for a number of possible inaccuracies in the crankshaft bearing. Given the abundant research material, this publication is limited to a selection of the most representative cases considered:*case no. 1: the axes of the individual main bearing sockets are perfectlycoaxial, while one of the axes of the crankshaft main journals (journal axis No. 4, counting from the camshaft wheel side) is moved upwards by 0.03 mm from the others;*case no. 2: all axes of the crankshaft journals are perfectly coaxial, while one of the axes of the main bearing sockets (socket axis No. 5, counting from the camshaft side) is shifted upwards by 0.03 mm from the others;*case no. 3: one of the axes of the main bearing sockets (socket axis No. 6, counting from the camshaft wheel side), is moved upwards by 0.03 mm from the others, and one of the axles of the crankshaft main journals (journal axis No. 4, counting from the camshaft side) is offset from the others downwards by 0.03 mm.The results of the tests are shown in the form of tables and diagramsrepresenting the values of reaction forces occurring in the vertical and horizontal plane on individual main bearings and in the form of examples of strain values presented for selected angular shaft positions.Table 2 and diagrams in Fig. 5 show (Polar and Cartesian coordinate system), values of reaction forces occurring in the vertical plane.Table3 and diagrams in Fig.6 show the values of reaction forces occurring in the horizontal plane for the variant formulated as case no. 1.Fig. 7 shows an example of the distribution of reduced strain occurring along the length of the shaft in an angular position equal to 180°.Table 4 and diagrams in Fig. 8 show (Polar and Cartesian coordinate system), the values of vertical reaction forces.Table 5 and diagrams in Fig. 9 show the values of horizontal reaction forces for the variant formulated as case no. 2.Table 6 and diagrams in Fig. 11 show (Polar and Cartesian coordinate system), the values of vertical reaction forces.Table 7 and diagrams in Fig. 12 show the values of horizontal reaction forces for the variant formulated as case no. 3.Given the specific difference of this case from the previously presented ones,the distribution of reduced stresses over the shaft length is shown at two opposite angular shaft positions.The angular position was initially taken equal to 0° (Fig. 13a) and the angular position after rotation of the shaft by 180° (Fig. 13b).Table 8 and diagrams in Figure 14 (Polar and Cartesian coordinate system) show in order to illustrate the differences between the reaction forces occurring in the case of a bearing system with geometrical deviations and a bearing system with no geometrical deviations, the vertical reaction forces for a crankshaft bearing system without geometrical deviations.The values of reaction forces are shown in Table 9 and in the diagrams in Fig.15.EVALUATION OF RESEARCH RESULTS AND CONCLUSIONThe research results presented in this publication have validated the purpose of their implementation. This includes the previously suggested significant influence of geometrical deviations of the crankshaft bearing system on the values of reaction forces in main bearings and strains in crankshafts. Values of vertical and horizontal reaction forces in bearings fluctuate as demonstrated within large ranges (which should be emphasized) due to the change of angular position of the shaft. This results in exceeding the permissible loads on the mainbearings resulting in accelerated wear during motor operation. Themultidirectional variability of bearing loads results in a particularly dangerous periodic loss of load bearing capacity.It is, therefore, necessary to carry out not only measurements of shapedeviations but also deviations in the position of the axles in relation to both the bearing socket hole set and the crankshaft's main journals set at the manufacturing or engine repair stage (Calculation of crankshafts for marine diesel engines, 2012; Shape and position tolerances of crankshafts – Engine technology specification MAN, 2010). Such possibilities are created by the developed measuring system with a controlled method for the implementation of variable reaction forces of the supports. The values of these forces, previously calculated using the MES (Nozdrzykowski and Chybowski, 2019;Nozdrzykowski, Chybowski and Dorobczyński, 2020) strength calculation programs, guarantee the elimination of shaft deflections and elastic deformations. Based on this solution, measurements can be carried out under conditions equivalent to those of a non-referenced measurement when the crankshaft is fixed in the counterpoints. One of the important advantages of the control unit is its stable dynamic performance characteristics. Consequently, the influence of the support conditions on the measurement of geometric values is negligible. This system allows for comprehensive measurements of geometric deviations of large crankshafts, realized in industrial conditions, as well as inrepair shipyards and workshops engaged in ship engine repairs.Łukomski, Z. (1972). Technologia spalinowa silników kolejowych i okrętowych [Exhaust gas technology of railway and marine engines]; WKiŁ: Warszawa.Kozłowiecki, H. (1974). Łożyska tłokowych silników spalinowych. Wydawnictwo Komunikacji i Łączności, Warszawa.Basiński, H., Szyndler, S. (1984). Cienkościenne Łożyska Ślizgowe – Informator dla konstruktorów Nr 1. Wytwórnia Łożysk Ślizgowych Bimet, Gdańsk-Oliwa.Barwell, F.T. (1984). Łożyskowanie. Wydawnictwo Naukowo-Techniczne, Warszawa.Nozdrzykowski, K. (2013). Metodyka pomiarów geometrycznych odchyłek powierzchni walcowych wielkogabarytowych elementów maszyn na przykładzie wałów korbowych silników okrętowych. Wydawnictwo Naukowe Akademii Morskiej w Szczecinie, Szczecin, Poland.Nozdrzykowski, K. (2017). Adjustment and analysis of forces in a flexible crankshaft support system. Journal of Machine Construction and Maintance, ProblemyEksploatacji, Nr 4(107), pp. 63-70.Nozdrzykowski, K. (2015). Prevention of Elastic Strains in Flexible Large Size Machine Parts with the Use of Elastic Support. Machine Dynamics Research, Nr 39(2), pp.Nozdrzykowski, K. (2011a). System do pomiarów odchyłek geometrycznych zespołu czopów głównych wału korbowego. Pomiary Automatyka Kontrola, 57(12), pp.Nozdrzykowski, K. (2011b). Sposób i urządzenie do pomiaru odchyłek kształtu i położenia osi czopów wału korbowego. Patent pending, application P.218653, Polish Patent Office.Calculation of crankshafts for marine diesel engines. Polish Register of Shipping. Publication 8/P, Gdańsk, Poland, 2012.Tolerancje kształtu i położenia dla wału korbowego – specyfikacja technologiczna silników MAN B&W [Shape and position tolerances of crankshafts – Engine technology specification MAN]. H. Cegielski S.A., Poznań, Poland, 2010.Nozdrzykowski, K., Chybowski, L. (2019). A Force-Sensor-Based Method to EliminateDeformation of Large Crankshafts during Measurements of Their Geometric Condition. Sensors, 19(16), 3507;doi:10.3390/s19163507.Nozdrzykowski, K., Chybowski, L., Dorobczyński, L. (2020). Model-Based Estimation of the Reaction Forces in an Elastic System Supporting Large-Size Crankshafts During Measurements of their Geometric Quantities, Measurement (2020), doi:Abstract: This article presents the results of a simulation, testing the variation of main bearing loads and strains in crankshafts caused by geometrical deviations of the bearing system to justify the necessity and purposefulness of measurements of both the shape and axes position deviations of crankshaft journals. Measurements of these deviations at the existing level of applied measuring techniques are significantly limited. The research also accentuates the practical implementation of a measuring system equipped with the so-called flexible support system for the measured object, developed at the Maritime University of Szczecin. This system makes it possible to eliminate elastic deformations of the crankshaft due to its own weight, whereby the measurements of geometrical deformations of the crankshaftscan be carried out with appropriate accuracy in conditions corresponding to the nonreference measurements when determining the object measured in counterpoints.The obtained results have fully confirmed the purposefulness of the conducted research and the validity of the theses.Keywords: modeling, simulation testing, loads and strains, crankshafts, bearing mounting system, geometrical deviations

The case of eccentricity of the elements forming the sliding bearing shown in Fig. 3b describes a journal as an ideal cylinder whose axis is non-deformable.Due to the interconnection and interaction of the interlinked, individual crankshafts are deformed differently, and the journal axes also undergoes a variety of bends and torsional elastic deformations. Consequently, this leads not only to a change in clearance but also to rapid, dynamic changes in the value of reaction forces in the bearings during shaft rotation. These observations are confirmed by the results of simulation tests carried out to assess the influenceof geometrical deviations of the bearing system upon the values of main bearing loads and strains in crankshafts.MODELING AND SIMULATION RESEARCH CONCERNING THEINFLUENCE OF GEOMETRICAL DEVIATIONS OF THE BEARING SYSTEMON THE VALUES OF MAIN BEARING LOADS AND STRAINS INSimulation tests were carried out using the Midas NFX 2019 simulation program based on FEM. The aforementioned crankshaft of the medium-rotation mainBuckau Wolf R8DV 136 engine of the vessel was modeled. The crankshaft was 3630 mm long and 9280 N heavy, with ten 149 mm diameter main journals and eight 144mm diameter crank journals, Fig. 4.Analysis of deformations and reaction forces, with consideration of therecommended clearance value and shaft weight in relation to the assumed inaccuracies with regard to the position of journal and socket axes of individual main bearings, was made for subsequent angular shaft positions, in the range of 0°-360°, changing its position every 15°. Simulation tests were conducted for a number of possible inaccuracies in the crankshaft bearing. Given the abundant research material, this publication is limited to a selection of the most representative cases considered:*case no. 1: the axes of the individual main bearing sockets are perfectlycoaxial, while one of the axes of the crankshaft main journals (journal axis No. 4, counting from the camshaft wheel side) is moved upwards by 0.03 mm from the others;*case no. 2: all axes of the crankshaft journals are perfectly coaxial, while one of the axes of the main bearing sockets (socket axis No. 5, counting from the camshaft side) is shifted upwards by 0.03 mm from the others;*case no. 3: one of the axes of the main bearing sockets (socket axis No. 6, counting from the camshaft wheel side), is moved upwards by 0.03 mm from the others, and one of the axles of the crankshaft main journals (journal axis No. 4, counting from the camshaft side) is offset from the others downwards by 0.03 mm.The results of the tests are shown in the form of tables and diagramsrepresenting the values of reaction forces occurring in the vertical and horizontal plane on individual main bearings and in the form of examples of strain values presented for selected angular shaft positions.Table 2 and diagrams in Fig. 5 show (Polar and Cartesian coordinate system), values of reaction forces occurring in the vertical plane.Table3 and diagrams in Fig.6 show the values of reaction forces occurring in the horizontal plane for the variant formulated as case no. 1.Fig. 7 shows an example of the distribution of reduced strain occurring along the length of the shaft in an angular position equal to 180°.Table 4 and diagrams in Fig. 8 show (Polar and Cartesian coordinate system), the values of vertical reaction forces.Table 5 and diagrams in Fig. 9 show the values of horizontal reaction forces for the variant formulated as case no. 2.Table 6 and diagrams in Fig. 11 show (Polar and Cartesian coordinate system), the values of vertical reaction forces.Table 7 and diagrams in Fig. 12 show the values of horizontal reaction forces for the variant formulated as case no. 3.Given the specific difference of this case from the previously presented ones,the distribution of reduced stresses over the shaft length is shown at two opposite angular shaft positions.The angular position was initially taken equal to 0° (Fig. 13a) and the angular position after rotation of the shaft by 180° (Fig. 13b).Table 8 and diagrams in Figure 14 (Polar and Cartesian coordinate system) show in order to illustrate the differences between the reaction forces occurring in the case of a bearing system with geometrical deviations and a bearing system with no geometrical deviations, the vertical reaction forces for a crankshaft bearing system without geometrical deviations.The values of reaction forces are shown in Table 9 and in the diagrams in Fig.15.EVALUATION OF RESEARCH RESULTS AND CONCLUSIONThe research results presented in this publication have validated the purpose of their implementation. This includes the previously suggested significant influence of geometrical deviations of the crankshaft bearing system on the values of reaction forces in main bearings and strains in crankshafts. Values of vertical and horizontal reaction forces in bearings fluctuate as demonstrated within large ranges (which should be emphasized) due to the change of angular position of the shaft. This results in exceeding the permissible loads on the mainbearings resulting in accelerated wear during motor operation. Themultidirectional variability of bearing loads results in a particularly dangerous periodic loss of load bearing capacity.It is, therefore, necessary to carry out not only measurements of shapedeviations but also deviations in the position of the axles in relation to both the bearing socket hole set and the crankshaft's main journals set at the manufacturing or engine repair stage (Calculation of crankshafts for marine diesel engines, 2012; Shape and position tolerances of crankshafts – Engine technology specification MAN, 2010). Such possibilities are created by the developed measuring system with a controlled method for the implementation of variable reaction forces of the supports. The values of these forces, previously calculated using the MES (Nozdrzykowski and Chybowski, 2019;Nozdrzykowski, Chybowski and Dorobczyński, 2020) strength calculation programs, guarantee the elimination of shaft deflections and elastic deformations. Based on this solution, measurements can be carried out under conditions equivalent to those of a non-referenced measurement when the crankshaft is fixed in the counterpoints. One of the important advantages of the control unit is its stable dynamic performance characteristics. Consequently, the influence of the support conditions on the measurement of geometric values is negligible. This system allows for comprehensive measurements of geometric deviations of large crankshafts, realized in industrial conditions, as well as inrepair shipyards and workshops engaged in ship engine repairs.Łukomski, Z. (1972). Technologia spalinowa silników kolejowych i okrętowych [Exhaust gas technology of railway and marine engines]; WKiŁ: Warszawa.Kozłowiecki, H. (1974). Łożyska tłokowych silników spalinowych. Wydawnictwo Komunikacji i Łączności, Warszawa.Basiński, H., Szyndler, S. (1984). Cienkościenne Łożyska Ślizgowe – Informator dla konstruktorów Nr 1. Wytwórnia Łożysk Ślizgowych Bimet, Gdańsk-Oliwa.Barwell, F.T. (1984). Łożyskowanie. Wydawnictwo Naukowo-Techniczne, Warszawa.Nozdrzykowski, K. (2013). Metodyka pomiarów geometrycznych odchyłek powierzchni walcowych wielkogabarytowych elementów maszyn na przykładzie wałów korbowych silników okrętowych. Wydawnictwo Naukowe Akademii Morskiej w Szczecinie, Szczecin, Poland.Nozdrzykowski, K. (2017). Adjustment and analysis of forces in a flexible crankshaft support system. Journal of Machine Construction and Maintance, ProblemyEksploatacji, Nr 4(107), pp. 63-70.Nozdrzykowski, K. (2015). Prevention of Elastic Strains in Flexible Large Size Machine Parts with the Use of Elastic Support. Machine Dynamics Research, Nr 39(2), pp.Nozdrzykowski, K. (2011a). System do pomiarów odchyłek geometrycznych zespołu czopów głównych wału korbowego. Pomiary Automatyka Kontrola, 57(12), pp.Nozdrzykowski, K. (2011b). Sposób i urządzenie do pomiaru odchyłek kształtu i położenia osi czopów wału korbowego. Patent pending, application P.218653, Polish Patent Office.Calculation of crankshafts for marine diesel engines. Polish Register of Shipping. Publication 8/P, Gdańsk, Poland, 2012.Tolerancje kształtu i położenia dla wału korbowego – specyfikacja technologiczna silników MAN B&W [Shape and position tolerances of crankshafts – Engine technology specification MAN]. H. Cegielski S.A., Poznań, Poland, 2010.Nozdrzykowski, K., Chybowski, L. (2019). A Force-Sensor-Based Method to EliminateDeformation of Large Crankshafts during Measurements of Their Geometric Condition. Sensors, 19(16), 3507;doi:10.3390/s19163507.Nozdrzykowski, K., Chybowski, L., Dorobczyński, L. (2020). Model-Based Estimation of the Reaction Forces in an Elastic System Supporting Large-Size Crankshafts During Measurements of their Geometric Quantities, Measurement (2020), doi:Abstract: This article presents the results of a simulation, testing the variation of main bearing loads and strains in crankshafts caused by geometrical deviations of the bearing system to justify the necessity and purposefulness of measurements of both the shape and axes position deviations of crankshaft journals. Measurements of these deviations at the existing level of applied measuring techniques are significantly limited. The research also accentuates the practical implementation of a measuring system equipped with the so-called flexible support system for the measured object, developed at the Maritime University of Szczecin. This system makes it possible to eliminate elastic deformations of the crankshaft due to its own weight, whereby the measurements of geometrical deformations of the crankshaftscan be carried out with appropriate accuracy in conditions corresponding to the nonreference measurements when determining the object measured in counterpoints.The obtained results have fully confirmed the purposefulness of the conducted research and the validity of the theses.Keywords: modeling, simulation testing, loads and strains, crankshafts, bearing mounting system, geometrical deviations

= 0.0005,

= 0.0005,