NFX案例|无人机仿真分析应用

1. INTRODUCTION

1.1. Background

Drone (UAV) was introduced to public people world widely in CES 2015. Especially the quadcopter which is one type of multicopters was very popular

in people who enjoy personal hobby and leisure. From this worldwide trend, domestic company had started to pay attention to drone (UAV) market.

Specially, the drone for agricultural and industrial purpose gave an impressive attention to government officers, industrial people and agricultural farmers. From this trend, one of companies which operated agricultural multicopters had a plan to improve its own vehicles. This company requested KARI to improve its existing representative multicopter since KARI had experienced in rotor blade development for over 20 years. The company’s multicopter (named as AFOX-1A) had 8 wooden propellers (beachwood). So, the locally fabricated and improved propeller was required to get vehicle’s efficiency. KARI decided to improve propeller primarily in viewpoint of new propeller’s aerodynamic design and structural design with light material after investigation of several items. For this short term program, KARI had setup the development process of high performance carbon propeller to finish earlier based on helicopter rotor blade’s experience.[1]

1.2 Program Overview

This program was launched on the 1st of March in 2015 and ended on the 30th of November in 2015 (9 months). This program was funded by KARI internal

budget. The final goal of this program is to develop new high performance carbon propeller for 32kg gross weight agricultural octocopter, to transfer technologies to company and to demonstrate in 2015 Creative Korea-Expo finally. The program goals such as 5% figure of merits improvement and

more payload were setup. Figure 1 shows some of representative multicopters.

At the 1st stage, ClarkY airfoil were surveyed as a primary candidate airfoil within limited time. Based on this airfoil, the thickness and curvature were

fitted after considering trailing edge minimum thickness, root thickness and so on. To analyze airfoil, XFOIL was used. It is viscous-panel method since this tool was effective in low Reynolds’s environment including transient model. Propeller’s planform design was conducted to minimize induced drag through optimize twist angle and chord length variation. To analyze this prediction,

QPROP tool was used which was worked based on Blade Element/Vortex method. For precise performance analysis, the CAMRADⅡ was used.

After comparison of each new designed propeller, the final propeller was selected. KARI in-house code (KSec2D) which is for blade sectional analysis

code was used to do sectional design of this propeller. From this sectional design, the propeller’s sectional properties were calculated. Finally, this

propeller was fabricated. After checking the sectional properties and weight, the ground rotational test of new fabricated carbon propeller was conducted.

At the stage, ground propeller rotational test was conducted. The both of existing and new developed propellers were conducted and measured the thrust and torque to get figure of merit. After verification of this ground test, the flight test was conducted in the company’s flight test site.

stage, ground propeller rotational test was conducted. The both of existing and new developed propellers were conducted and measured the thrust and torque to get figure of merit. After verification of this ground test, the flight test was conducted in the company’s flight test site.

The performance improvement was verified from this flight test finally. [2-3]. Figure 2 shows original octocopter and KARI’s developed new propellerinstalled

octocopter in this development program.

2. MAIN RESEARCH ACTIVITIES

This sections describes main research activities related to develop new carbon propeller. First, aerodynamic design and analysis was described. Second, propeller design and performance analysis were described in detail. Structural design and analysis was described. And dynamic and load analysis was shown. Fabrication and Qualification of carbon propellers were described. Finally ground and flight test were described

2.1. Aerodynamic Design & Analysis

For the selection of the airfoil, the flow conditions applied to the propeller blades should be checked After confirming Reynolds number corresponding to

the rotational speed, the airfoil is selected and airfoil aerodynamic data base (lift and drag coefficients) is calculated using XFOIL(viscous-panel method).

Since the rotational speed is less than Mach No.0.4, the incompressible airfoil solver XFOIL is suitable for use. In order to compare the performance of the

designed propeller, the shape of the baseline propeller was confirmed by 3D scanning. The aerodynamic force DB of baseline propeller airfoil is calculated under the same flow conditions of design propeller airfoil.

Modified Clark-Y airfoil was selected for the airfoil considering the Reynolds number range and the operating rotational speed. The selected airfoil is an

airfoil modified from the Clark-Y airfoil [1] considering its composition and performance, and it considers the trailing edge thickness including the actual manufacturing error.

2.2. Propeller Design and Performance Analysis

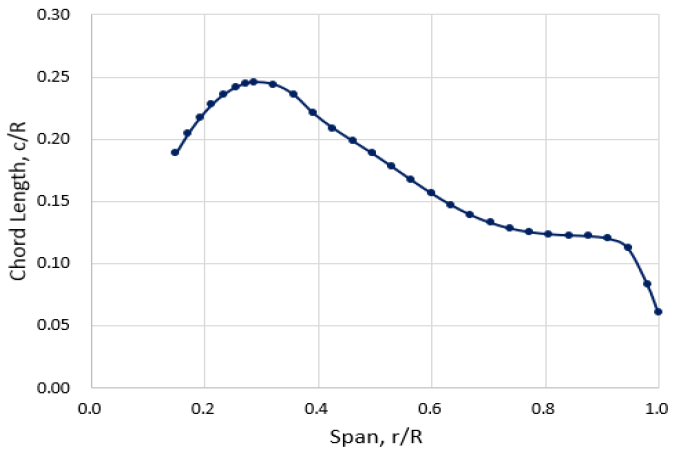

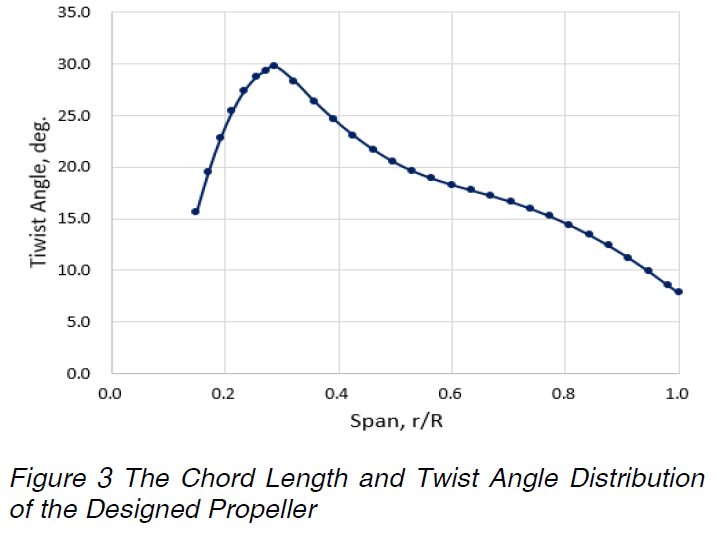

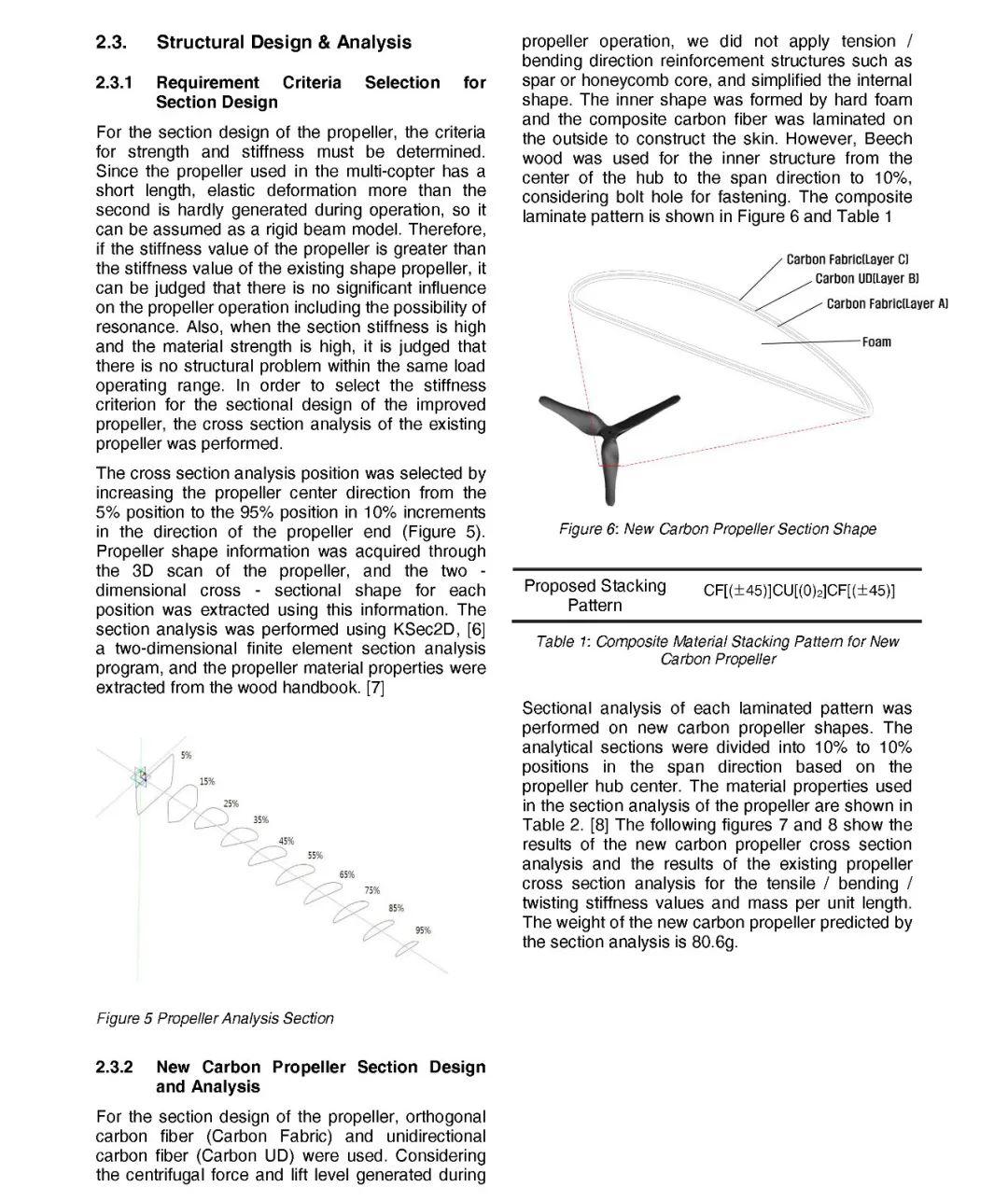

The propeller planform design was implemented by QMIL/QPROP program developed by Mark Drelar of MIT University [4]. The QMIL/QPROP program generate the propeller chord length and twist angle distribution along the span to minimize the induced power for given propeller radius, number of blades, rotational speed, sectional lift coefficient of airfoil and the required thrust condition. The propeller root location and maximum cord length were set to 10% and 30% of the propeller radius and the root thickness of the airfoil was

increased to ensure the structural safety margin. The distribution of chord length and twist angle in the root region of the propeller were modified from

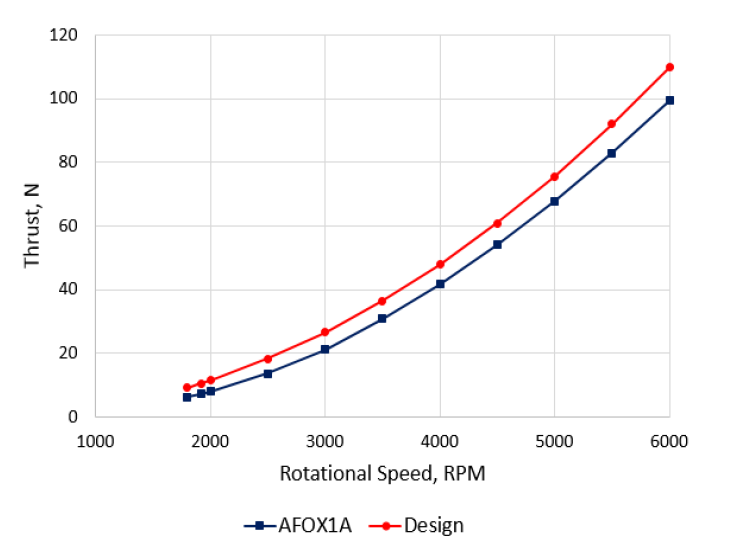

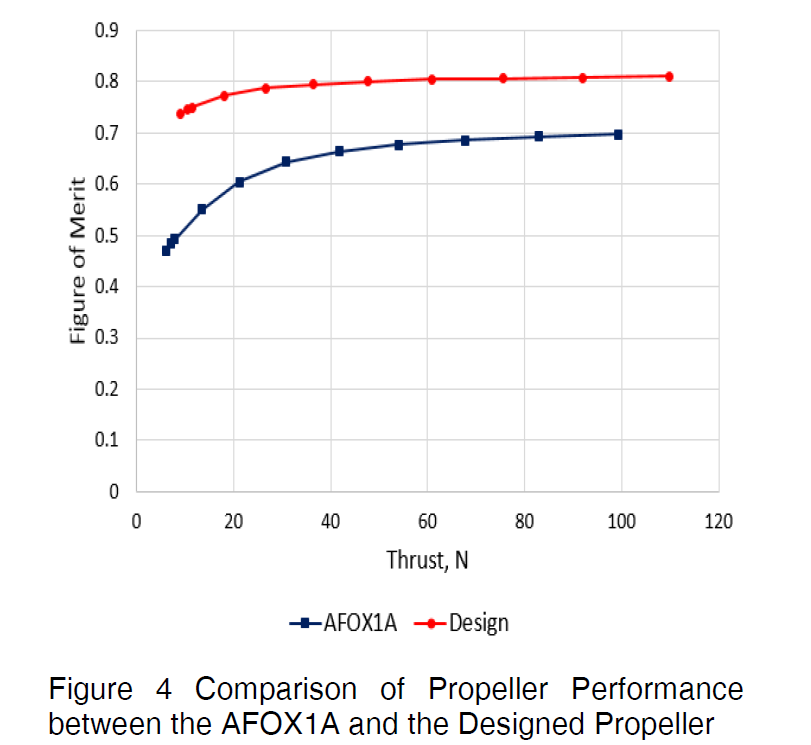

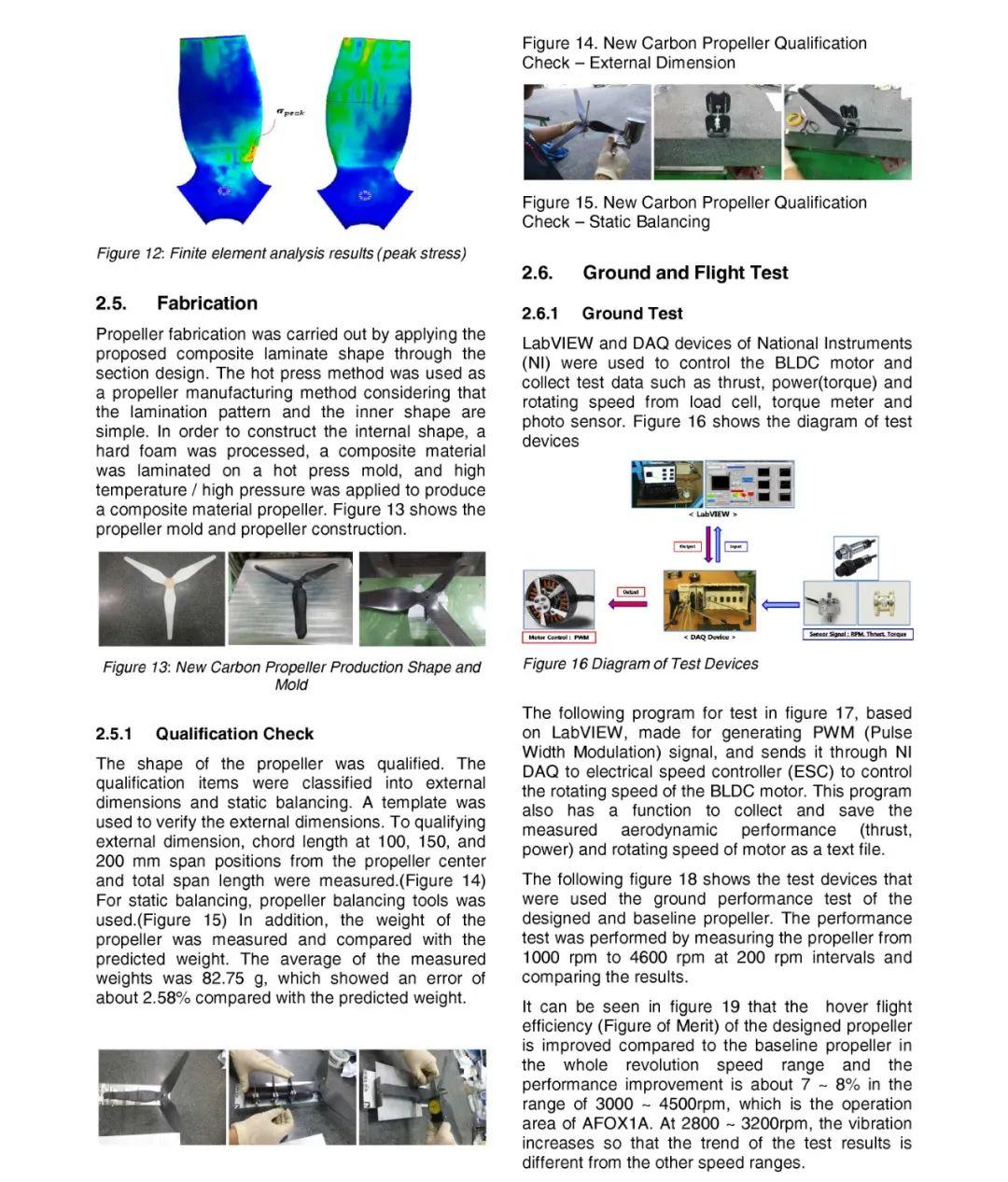

the result of QMIL/QPROP. Figure 3 shows the distribution of cord length and twist angle along the span of the propeller. Figure 4 shows aerodynamic performance of the designed propeller compared to the propeller applied to the original multicopter (AFOX1A). The analysis was conducted by using CAMRAD-II, which is comprehensive aeromechanics analysis program [5]. Thrust of the designed propeller is much higher than the propeller of AFOX1A on full

range of rotational speed. The required power also reduced than that at the same thrust condition.

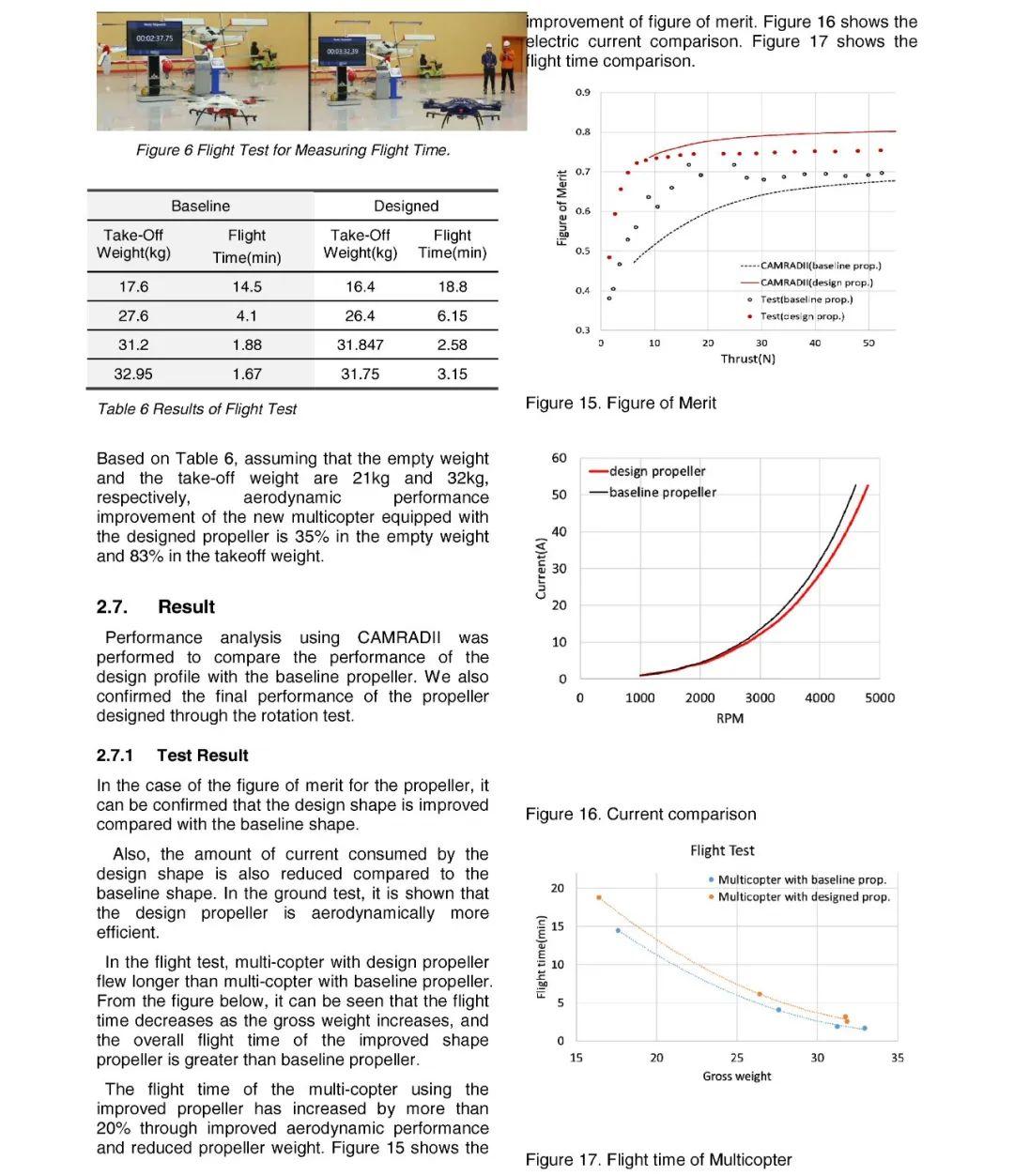

3. CONCLUSION

This paper describes the general overview of new carbon propeller development for 32kg Gross Weight agricultural multicopter (Octocopter drone).

Based on the design process of helicopter rotor blade, KARI conducted the carbon propeller development. All tools and facilities related to develop helicopter rotor blade were applied in this program. This paper shows the main research activities such as aerodynamic design and analysis, structural design and analysis, fabrication and investigation, ground and flight test. Finally the flight time of the multicopter using the improved carbon propeller has increased compared to existing beachwood propellers by more than 20% through improved aerodynamic performance and reduced carbon propeller weight. This results was campaigned in 2015 Creative Korea-Exposition.

Through this research, KARI had a good opportunity in drone industry to localize carbon propeller and improve drone performance.

4. REFERENCES

[1] http://mselig.ae.illinois.edu/ads/coord_database.html

[2] http://www.crn.com/slide-shows/channelprograms/300075327/the-top-25-productsfrom-ces-2015.htm/pgno/0/19

[3] J. Gordon Leishman, “Principles of Helicopter Aerodynamics”, University of Maryland, Cambridge University Press 2006

[4] Drela, M., QProp Propeller/Windmill Analysis and Design, Ver. 1.22, Massachusetts Institute of Technology, Cambridge, MA, http://web.mit.edu/drela/Public/web/qprop, 2011

[5] Johnson, W., CAMRAD II, Comprehensive Analytical Model of Rotorcraft Aerodynamics and Dynamics, Release 4.9, 2012

[6] Park, I. J., Jung, S. N., Cho, J. Y., and Kim, D.H., “A Study on Calculation of Cross-Section Properties for Composite Rotor Blades Using Finite Element Method,” Journal of the Korean Society for Aeronautical and Space Sciences, Vol. 37, No. 5, 2009, pp. 442~449.

[7] Kretschmann, D. E., Wood Handbook: wood as an engineering material, Centennial Edition, United States Department of Agriculture Forest Service, Madison, 2010,Chapter 5

[8] Park, S. O., Lee, M. H., Woo, D. H., and Shin, J. W., “Composite Material Allowables for Development of EAV”, KARI Report, 2014

本文来源于网络,侵删!

相关文章,在仿真秀官网搜索:

MeshFree-四旋翼无人机单翼受压分析

模态分析(Modal Analysis)