基于结构应力方法的焊接结构疲劳评估及实例分析(上篇)

本文摘要(由AI生成):

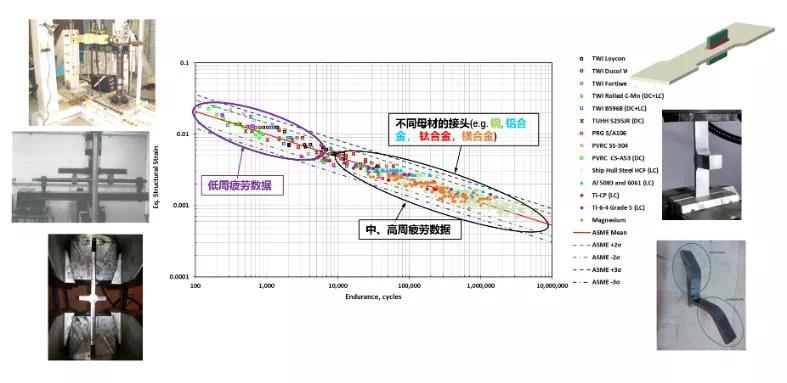

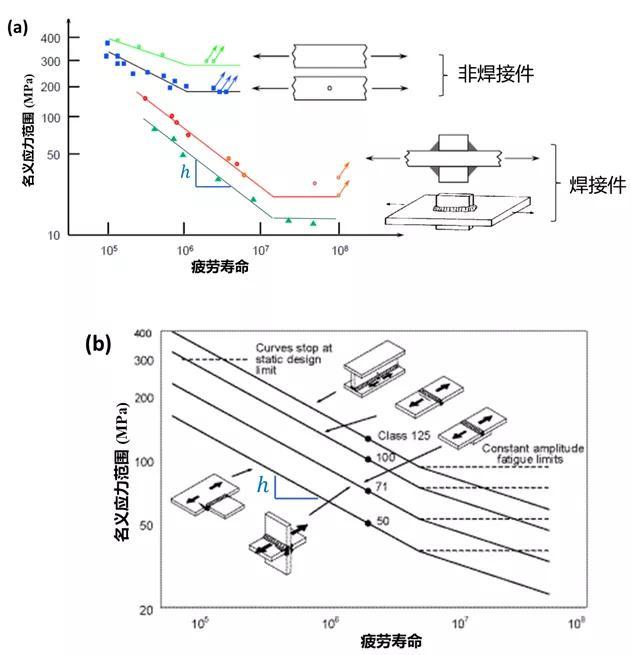

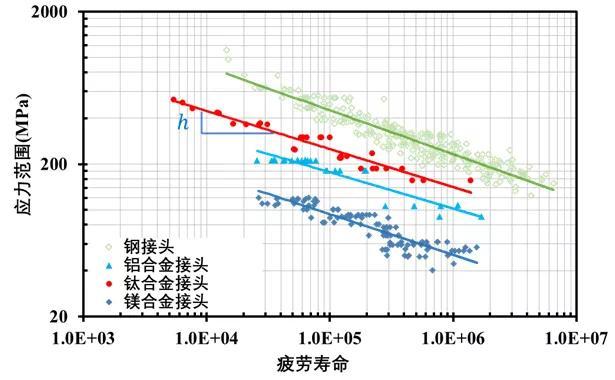

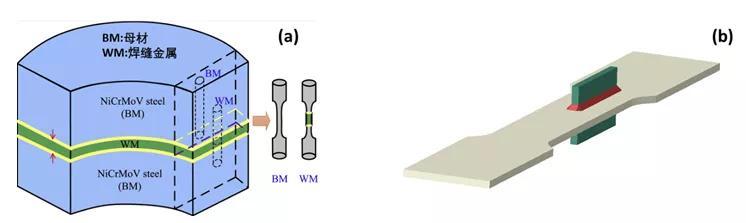

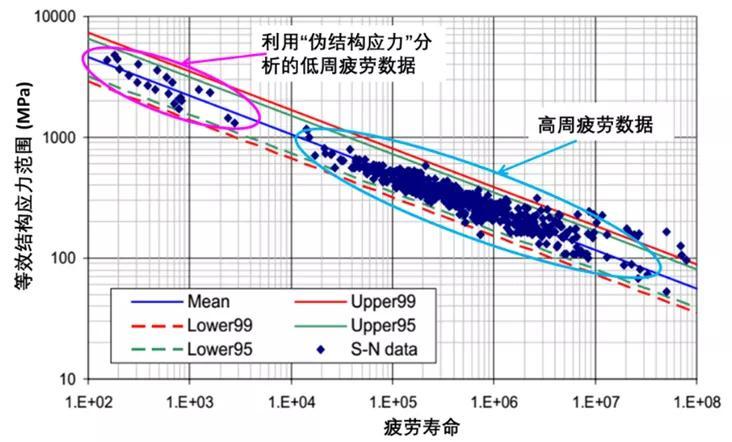

本文主要介绍了焊接接头疲劳问题的特殊性以及目前焊接疲劳研究的两大方向。焊接接头疲劳问题的特殊性在于焊接接头组织性能不均匀,应力集中大,存在残余应力、变形甚至焊接缺陷,导致焊接接头往往是整体结构中最容易发生疲劳破坏的位置。目前焊接疲劳研究的两大方向包括接头区域材料的疲劳行为研究和整体接头结构的疲劳控制参数研究。前者的研究对象大多是从接头上截取的小尺寸标准试件,而后者的研究对象则是接头结构整体。

一、写在文前

二、国内外研究现状评述

1、焊接接头疲劳问题的特殊性

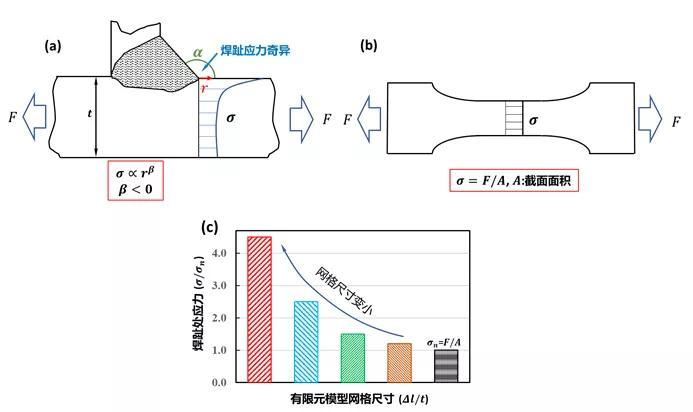

与该点到焊趾根部的距离r的关系为

与该点到焊趾根部的距离r的关系为 。其中

。其中 是焊趾角度

是焊趾角度 的函数,且

的函数,且 , 所以从理论上讲,当

, 所以从理论上讲,当 时,焊趾根部的应力趋于无穷。这与传统的狗骨拉伸试样很不相同。如图 1(b)所示,在一般用于材料疲劳试验的狗骨试样中,材料所承受的应力即为名义应力,可以明确确定。焊接接头处应力的奇异性直接导致了在传统有限元计算中,焊趾处的应力网格敏感。亦即,接头附近有限元网格尺寸越小,计算得到的应力越大,并且应力不会随着网格尺寸变小而收敛(见图 1(c))。

时,焊趾根部的应力趋于无穷。这与传统的狗骨拉伸试样很不相同。如图 1(b)所示,在一般用于材料疲劳试验的狗骨试样中,材料所承受的应力即为名义应力,可以明确确定。焊接接头处应力的奇异性直接导致了在传统有限元计算中,焊趾处的应力网格敏感。亦即,接头附近有限元网格尺寸越小,计算得到的应力越大,并且应力不会随着网格尺寸变小而收敛(见图 1(c))。

2、目前焊接疲劳研究的两大方向

[1] 董磊 and 崔慕春, 三桥刚性矿车车架的疲劳寿命分析及优化.自动化应用, 2021(01): p. 138-140.

[2] Lazzarin, P., T. Lassen,and P. Livieri, A notch stress intensityapproach applied to fatigue life predictions of welded joints with differentlocal toe geometry. Fatigue & Fracture of Engineering Materials &Structures, 2003. 26(1): p. 49-58.

[3] Shen, W., et al., A simplified method for evaluating singularstress field and fatigue strength of U-shaped notch. Marine Structures,2020. 72: p. 102770.

[4] Lou, B., N. Barltrop, andJ. Zhang, Geometry parameter method toestimate stress intensity in V-notched plate and a small crack ahead fromV-notch apex. Thin-Walled Structures, 2020. 154: p. 106801.

[5] Gurney, T.R., Fatigue of welded structures. 1979: CUPArchive.

[6] Maddox, S.J., Fatigue strength of welded structures.1991: Woodhead publishing.

[7] Maddox, S., Hot-spot stress design curves for fatigueassessment of welded structures. International Journal of Offshore andPolar Engineering, 2002. 12(02).

[8] 王苹, et al., 7N01 铝合金十字接头抗疲劳设计.焊接学报, 2020. 40(10): p. 20-24.

[9] Xing, S. and P. Dong, Fatigue of titanium weldments: SN testingand analysis for data transferability among different joint types. MarineStructures, 2017. 53: p. 1-19.

[10] Zhou, W., et al., Evaluation of magnesium weldment fatiguedata using traction and notch stress methods. International Journal ofFatigue, 2020. 138: p. 105695.

[11] Guo, S.-J., et al., A comparative study on the cyclic plasticityand fatigue failure behavior of different subzones in CrNiMoV steel weldedjoint. International Journal of Mechanical Sciences, 2019. 150: p. 66-78.

[12] Tang, J.-Q., et al., Comparison on the cracking susceptibility ofdifferent low alloy steel weldments exposed to the environment containing wetH2S. Engineering Failure Analysis, 2006. 13(7): p. 1057-1064.

[13] Luo, H., et al., Experimental investigation on theheterogeneous ratchetting of SUS301L stainless steel butt weld joint duringuniaxial cyclic loading. International Journal of Fatigue, 2017. 105: p. 169-179.

[14] Wang, Q., et al., Mixed mode fatigue crack growth behavior ofNi-Cr-Mo-V high strength steel weldments. International Journal of Fatigue,2017. 102: p. 79-91.

[15] Zhang, X. and R. Bao, Evaluation of the intrinsic crack growthrates of weld joints. International journal of fatigue, 2011. 33(4): p. 588-596.

[16] 吴圣川, et al., 激光-电弧复合焊接 7075-T6 铝合金疲劳断裂特性. 2012.

[17] Sai, M.S., et al., A systematic review of effect of differentwelding process on mechanical properties of grade 5 titanium alloy.Materials Today: Proceedings, 2020. 21:p. 948-953.

[18] 张玉财, et al., 钎焊接头的蠕变损伤与寿命预测.机械工程学报, 2021: p. 1-18.

19] Luo, H., et al., Experimental study on the whole‐life heterogeneous ratchetting and ratchetting‐fatigue interaction of SUS301L stainless steel butt‐welded joint. Fatigue & Fracture ofEngineering Materials & Structures, 2020. 43(1): p. 36-50.

[20] Lin, S., et al., Effect of cyclic plastic deformation onmicrostructure and mechanical properties of weld metals used for reel-laypipeline steels. Materials Science and Engineering: A, 2018. 737: p. 77-84.

[21] Ye, D., et al., Use of instrumented indentation testing tostudy local mechanical properties of 304L SS welded joints subjected tolow-cycle fatigue loadings. Materials Science and Engineering: A, 2013. 564: p. 76-84.

[22] Shang, Y.-B., et al., In-situ SEM study of short fatigue crackpropagation behavior in a dissimilar metal welded joint of nuclear power plant.Materials & Design, 2015. 88: p.598-609.

[23] Dong, P., Z. Cao, and J.Hong. Low-cycle fatigue evaluation usingthe weld master SN curve. in ASMEPressure Vessels and Piping Conference. 2006.

[24] Kang, G. and H. Luo, Review on fatigue life prediction models ofwelded joint. Acta Mechanica Sinica, 2020. 36: p. 701-726.

[25] 白亚男, et al., 基于热点应力的罐车焊接钢结构疲劳.焊接学报, 2019. 40(04): p.90-94 124 164-165.

[26] Radaj, D., Generalised Neuber concept of fictitiousnotch rounding, in Advanced methodsof fatigue assessment. 2013, Springer. p. 1-100.

[27] Taylor, D., A mechanistic approach to critical‐distance methods in notch fatigue. Fatigue& Fracture of Engineering Materials & Structures, 2001. 24(4): p. 215-224.

[28] Xiao, Z.-G. and K. Yamada, A method of determining geometric stress forfatigue strength evaluation of steel welded joints. International Journalof Fatigue, 2004. 26(12): p.1277-1293.

[29] Lazzarin, P., et al., Some advantages derived from the use of thestrain energy density over a control volume in fatigue strength assessments ofwelded joints. International Journal of Fatigue, 2008. 30(8): p. 1345-1357.

[30] Radaj, D., C. Sonsino, andD. Flade, Prediction of service fatiguestrength of a welded tubular joint on the basis of the notch strain approach.International journal of fatigue, 1998. 20(6):p. 471-480.

[31] Dong, P., A structural stress definition and numericalimplementation for fatigue analysis of welded joints. International Journalof Fatigue, 2001. 23(10): p.865-876.

[32] Dong, P., et al., A structural strain method for low-cyclefatigue evaluation of welded components. International Journal of PressureVessels and Piping, 2014. 119: p.39-51.

[33] Pei, X. and P. Dong, An analytically formulated structural strainmethod for fatigue evaluation of welded components incorporating nonlinearhardening effects. Fatigue & Fracture of Engineering Materials &Structures, 2019. 42(1): p. 239-255.

[34] Pei, X., P. Dong, and M.H.Kim, A simplified structural strainmethod for low-cycle fatigue evaluation of girth-welded pipe components.International Journal of fatigue, 2020. 139:p. 105732.

[35] Pei, X., P. Dong, and S.Xing, A structural strain parameter for aunified treatment of fatigue behaviors of welded components. InternationalJournal of Fatigue, 2019. 124: p.444-460.

[36] Mei, J. and P. Dong, An equivalent stress parameter formulti-axial fatigue evaluation of welded components including non-proportionalloading effects. International Journal of Fatigue, 2017. 101: p. 297-311.

[37] Mei, J., et al., An overview and comparative assessment ofapproaches to multi-axial fatigue of welded components in codes and standards.International Journal of Fatigue, 2021. 146:p. 106144.

[38] Pei, X., et al., A multi-axial vibration fatigue evaluationprocedure for welded structures in frequency domain. Mechanical Systems andSignal Processing, 2022. 167: p.108516.

[39] Wang, P., et al., Analysis of weld root fatigue cracking inload-carrying high-strength aluminum alloy cruciform joints. InternationalJournal of Fatigue, 2020.139: p.105735.

[40] Yu, Y., et al., Fatigue resistance characterization offrictions stir welds between complex aluminum extrusions: An experimental andfinite element study. International Journal of Fatigue, 2020. 141: p. 105861.

[41] Wei, Z., et al., A simplified approach to estimate thefatigue life of full-scale welded cast steel thin-walled tubular structures.Thin-Walled Structures, 2021. 160:p. 107348.

(完)

作者简介:裴宪军博士 东南大学副研究员 仿真秀专栏作者

哈尔滨工业大学焊接技术与工程专业本科, 密歇根大学船舶与海洋工程专业博士,博士期间师从国际著名焊接结构专家董平沙教授。曾担任斯伦贝谢道尔实验室研究员,密歇根大学助理研究员工作,现任东南大学机械工程学院副研究员。

长期从事焊接结构疲劳断裂行为、结构完整性研究、材料加工(焊接/连接)等方面研究,取得了多项创新成果。参与了美国机械工程师学会(ASME)中设计焊接接头疲劳分析的修订工作。发表各类论文30余篇,申请国际专利两项。